Contents

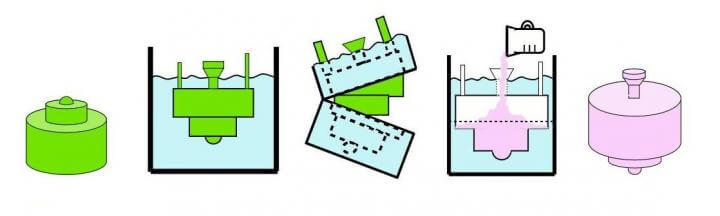

Vacuum Casting Overview

There are different types of casting processes wont to manufacture parts from metal and polymer material. Sand casting is one of the oldest and cheapest processes, while at a better end, there are other processes like die casting and investment castings.

The method is seemingly simple. One pours material into a mold, and it hardens to make the part. The technique isn’t devoid of shortcomings. During the casting processes, air may remain within the material and mold, resulting in the formation of blowholes. These are termed as defects and cause rejection of parts.

To counter these rejects, a new technique of casting was invented. That is vacuum mold casting. The process is designed to get similar products and parts, only that they are free from the casting defects.

Read on as we guide you on everything that you should know about vacuum casting.

What is Vacuum Casting?

This is a casting process that uses a vacuum to draw any liquid material into the mold. Vacuum casting is employed when air entrapment may be a problem with the mold.

Additionally, the method is often used when there are intricate details and undercuts on the mold. Also, it’s applied if the fabric wont to make the mold is fiber or a reinforced wire.

The process is usually called thermoforming because the manufacturing process involves rapid prototyping where the plastic sheets are preheated. The materials are preheated in an automatic vacuum casting machine until they’re soft and pliable.

The process is slower, but it leads to parts that are freed from common casting defects. It’s equally as useful for metal because it is for polymer components casting.

Unlike metal, which will be melted again and be reused, some polymers, especially thermosets or polymers like polyurethane, can’t be reused. The part has got to be scrapped. Vacuum casting works out on issues and helps one to manufacture parts that are perfect.

How Does a Vacuum Casting Machine Work

The vacuum casting process follows various process stages to manufacture raw materials to complete refined products. Everything takes place in the casting vacuum chamber. Let’s look at the step-by-step process of how to vacuum cast works:

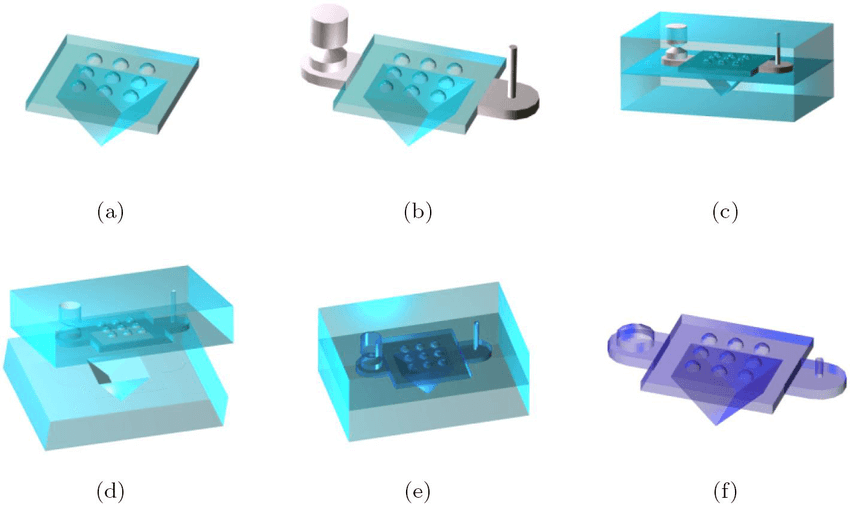

Step 1: Creation of 3D Model

The vacuum casting process requires you to possess a high-quality master model. The high-quality master model is often the economic part itself. Additionally, you’ll use a model created using stereolithography, which may be a case for the prototyping applications.

You should always make sure that the master model getting used is of the right dimensions and appears. This is often to make sure that no flaws are transferred to the model prototype after finishing the method.

Step 2: The curing process

The original model is then encapsulated into a two-part synthetic rubber mold. The mold is cured under high temperatures to make sure that the two parts stay together. This is often wont to strengthen the mold and make it more durable.

After the mold is cured, it’s cut to reveal a cavity in the middle, which has the precise dimensions of the master model. After the mold is cut into two, it’s placed within the chamber. Then, later on, the mold is crammed with the designated material to form a product.

Step 3: Vacuum chamber for resin casting

The next stage of vacuum casting entails filling the mold with the designated material. The resin replicates the characteristics of commercial material. The resin material is typically mixed with metallic powder or any coloring pigment to realize aesthetic or specific functional properties.

After the mold is crammed with the resin material, it’s placed within the chamber. It’s set within the chamber to make sure that there are not any air bubbles within the mold.

The mold is put during a chamber during a vacuum mold machine. Thereafter, the chamber is fully evacuated with the assistance of the air pump within the machine. The resin flows into the cavity and fills it completely without introducing any air gaps. This is often to make sure that the ultimate product isn’t ruined or damaged.

Step 4: The final curing process

The resin is placed within the oven for the ultimate cured stage. The mold is cured in high temperatures to make sure that the fabric is robust and sturdy. The silicone mold is far away from the mold, so that it is often utilized in making more prototypes.

After the prototype is far away from the mold, it’s painted and decorated. The painting and styles are wont to make sure that the merchandise features a gorgeous final look.

Benefits of Vacuum Casting

Why should I choose vacuum casting over other types of casting methods? There are tons of benefits that you are likely to gain from this casting method. Here are some advantages of vacuum casting for molds;

1. Accurate casting

When compared to other methods of casting that are used in 3D manufacturing, vacuum casting is able to stand out mainly because of its high-precision level.

Will the final product meet the specifications of the design? This is the most common question that people ask when it comes to casting. With vacuum casting, the answer is yes.

It ensures that the ultimate product has great attention to the small details. The ultimate product finishes up looking just like the original product.

Every attention to detail under consideration is taken into account and brought into account. Even when the first product has the foremost complex geometry, the ultimate product seems like print design.

2. Quality products and parts

An accurate vacuum casting process is likely to have a direct impact on the quality of the final products and parts.

The products made from the vacuum casting method are of top quality. Also, the utilization of resin allows you to settle on the proper material to be utilized in making of the ultimate product.

This allows you to possess a more extensive choice of flexibility, hardness and rigidity you would like in your products. Also, this features a great influence on the final appearance of the merchandise since the fabric used plays a serious role.

3. Cheap mold cost casting

Using the vacuum casting process to form the merchandise is more economical. This is often because the method uses silicon to create the molds. Vacuum cast is affordable as compared to other casting techniques such as investment molding. To make things better, the process is still able to make great final products.

Moreover, the fabric allows you to form more products from the mold. This makes this process more cost-effective as compared to the utilization of 3D printing. As always, the best way of saving the cost is by choosing affordable vacuum cast companies in China.

4. Fast production

You have a large volume of products and parts to be manufactured within a short time-frame? Consider going for vacuum casting services. The process won’t disappoint you when it comes to time.

This mold casting method is fast, and it takes you less time to end, making the finish products. You’ll take seven to 10 days to form around 50 functioning prototype parts.

This method is amazing once you are making tons of products. Additionally, it’s great once you are working towards meeting a deadline.

5. Flexible and adaptable

Vacuum casting for molds can be used on different types of materials regardless of their density and chemical properties. The process can be used on plastics, polymers and even polyurethanes.

The molding process can also be used to mold different sizes of materials. You can use it in both large and small parts and even products. Also, the design of the material won’t be a limiting factor when it comes to vacuum cast. Complex designs can be obtained from the process.

Applications of Vacuum Cast Molding

Vacuum cast molding has a wide range of applications. It can be used for both domestic, hobby and commercial applications. Some of the vacuum castings use include;

1. Food and drinks

The food and beverage industry uses this product for the packaging of their final products. Vacuum casting is often utilized in making plastic bottles and tins.

Since this process is often wont to make products faster and on an outsized scale, it’s preferred in most of those industries.

2. Household products

A good number of household products are made using the vacuum casting process. Products that we use on a daily basis such as washing detergents, food processing, and cosmetics are made using this process.

If you get your products from high-quality companies, there are high chances that they use the casting vacuum process to form the products.

3. Commercial and industrial products

This process is employed to form commercial products that will be utilized in packaging. To mention some of the products that are made using this process include mobile cases, sunglasses, food and drinks packaging, and pens.

This method creates employment for people that want to venture within the selling off a number of these products.

Vacuum Casting Services China: Roche Industry

There is no doubt that the vacuum mold casting method is a reliable method of manufacturing products.

To get the full benefits of this manufacturing method, start by choosing the best vacuum cast manufacturers in China.

This is what we at Roche industry offer. We give our customers top quality vacuum casting services that will exceed their expectations.

Don’t hesitate to contact us if you have any questions about vacuum casting.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Handbook: The Ultimate Guide To Urethane Casting

Handbook: The Complete Guide To Investment Casting

Handbook: The Ultimate Guide to Metal Casting

Handbook: The Ultimate Guide to Sand Casting

Handbook: Everything You Need to Know About Resin Casting