What are aluminum alloys? And how can one determine the best one for a specific project? These are among the frequently asked questions about aluminum. Aluminum alloys are metal compounds that are manufactured by the addition of a certain percentage of other metallic elements into pure aluminum. The result is often a new and more useful metal. The items that are added to aluminum are called alloying elements, and they determine the quality of the new metal formed. Since many alloying elements can be added to pure aluminum, there are equally various alloys of aluminum. Every alloy has its attributes based on its composition. This article aims to compare two of the most common alloys of aluminum that fall in the 6xxx series, 6061 and 6063 aluminum alloy. The physical properties, strength, and the applications of these aluminum alloys are highlighted in this post to help point you in the right direction should you decide to buy the right one for your project. What are the Differences between 6061 vs 6063 aluminum?

Contents

6061 Aluminum alloy

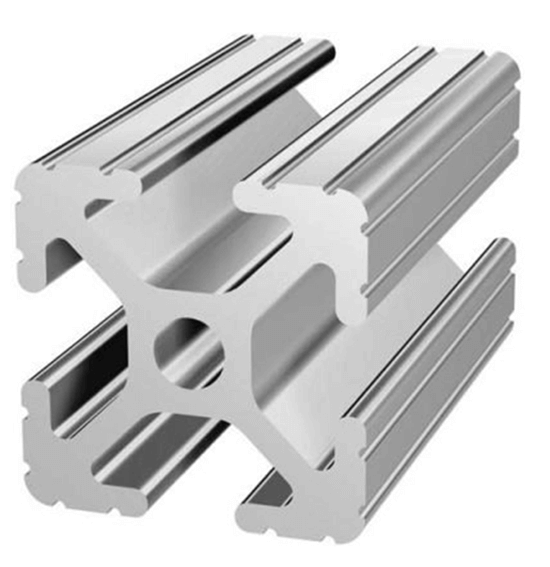

The 6061 aluminum is one of the most excellent general-purpose aluminum alloys that can be used in a wide range of applications. This is mainly due to the metal’s perfect formability, weldability, moderate resistance to corrosion, and its reasonably high strength. These qualities make the 6061 aluminum a highly versatile alloy. 6061 aluminum has a density of 2.7g/cm3 with the main alloying elements used to make it being magnesium and silicon. 6061 aluminum alloy is often strengthened using the heat treatment process to produce various ranges of tempers like 6061-T4 and 6061-T6. Due to its excellent strength over the rest of the 6xxx series alloys, 6061 aluminum is the most used aluminum alloy. The mechanical strength of this alloy is down to its chemical composition and response to precipitation hardening. If your project requires light but heavy-duty metal, the 6061 aluminum should be your alloy of choice.

6063 Aluminum alloy

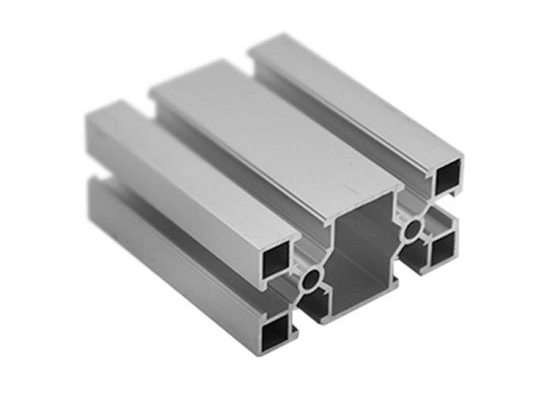

The 6063 aluminum is commonly called architectural aluminum because it’s widely used as a structural material. 6063 aluminum alloy has an excellent response to extrusion and can also be drawn into cross-sectional shapes. Besides, it has the most resistance to corrosion and holds a perfect surface finish. These attributes make it an ideal choice for decorative parts than other 6xxx series alloys. Both 6061 and 6063 aluminum have a density of 2.7g/cm3. Additionally, 6063 aluminum can be heat-treated to give the most common temper, which is 6063-T6 aluminum.

6061 and 6063 aluminum do not differ significantly. However, 6063 aluminum has lower strength and better resistance to corrosion which makes it a perfect choice for extrusion projects. Additionally, it can be formed into complex shapes that do not weather easily and have great surface finishes at the same time. These pros make 6063 aluminum a popular alloy for extrusion.

Comparing 6061 and 6063 Aluminum

Both 6061 and 6063 aluminum come from the same series, and they, therefore, have the same chemical compositions. This factor makes it difficult to distinguish between the two aluminum alloys from a materials properties viewpoint. However, it is possible to compare the 6061 and 6063 aluminum alloys based on their applications and usefulness. Additionally, the differing strength of 6061 and 6063 aluminum make a good point for the comparison. It is equally essential to note that the strength is based on the heat-treatment method. The comparison taken in this post is based on the 6061-T6 and 6063-T6.

1. Yield strength

The yield strength of 6061 is significantly higher than that of 6063. For this reason, most people choose 6061 aluminum over 6063 aluminum for projects that require strength such as in making firearms part and bike frames.

2. Ultimate strength

This is the measure of the maximum stress that can be obtained during permanent deformation. The ultimate strength is not as important as the yield strength. The ultimate strength is only preferred in projects that require plastic deformation. In this section, 6063 aluminum has the lowest ultimate strength and is therefore used for extrusion projects that require plastic deformation.

3. Fatigue strength

This is the measure of response to cyclical loading. 6061 aluminum is the perfect choice for projects that require cyclical loading such as in making aircraft and marine vehicles since it has higher fatigue strength compared to 6063 aluminum.

4. Bearing yield strength

This is how much a material responds in joining arrangements, for instance, when two plates are joined. The bearing strength is the maximum stress that cannot cause hole-joint crack when the parts are under pressure. This quality is useful in scaffolding. 6061 aluminum alloy has a higher bearing yield strength than 6063 aluminum alloy and is, therefore, the best choice for such applications.

5. Hardness

This is also the ductility, surface quality, and generally the material strength of a material. This quality is often scalable and can be measured based on various scales. 6061 and 6063 aluminum alloys are not significantly hard. However, these metal alloys are ductile enough to be formed. At the same time, they can resist deformation because of their strength. 6061 aluminum is, however, the perfect choice for applications that require hardness.

6. Machinability

This is the performance of a material when it is being milled, turned, or die-casted. There are very many ways of machining metals, and this approach is very subjective in comparing material properties. 6061 aluminum has the best response to machining than 6063 aluminum. For this reason, 6061 aluminum is mostly preferred for projects that require machining procedures. 6063 aluminum alloy can also be machined, but it does not perform as well as 6061.

The bottom line

This post has presented a comparison between 6061 and 6063 aluminum alloys based on their strength, properties, and applications. It is essential to understand that each alloy is best suited for specific projects because they compare differently. Besides, choosing the right material requires an evaluation of the project and the properties that would complete it better. Both 6061 and 6063 aluminum alloys have varied qualities even though they have the same chemical composition.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links: