Steel is quite a common type of metal that features a wide range of applications. It is used for creating all types of products, from aerospace to kitchenware. Such diverse applications require a flexible material—and steel fits the bill. The desirable properties of steel are the rationale behind its massive popularity.

‘Steel’ is a term that actually describes a whole family of metal alloys, with many application-specific grades. However, most of the people understand steel in two broad categories: steel and chrome steel. In fact, when buying steel, you will need to choose from these two types.

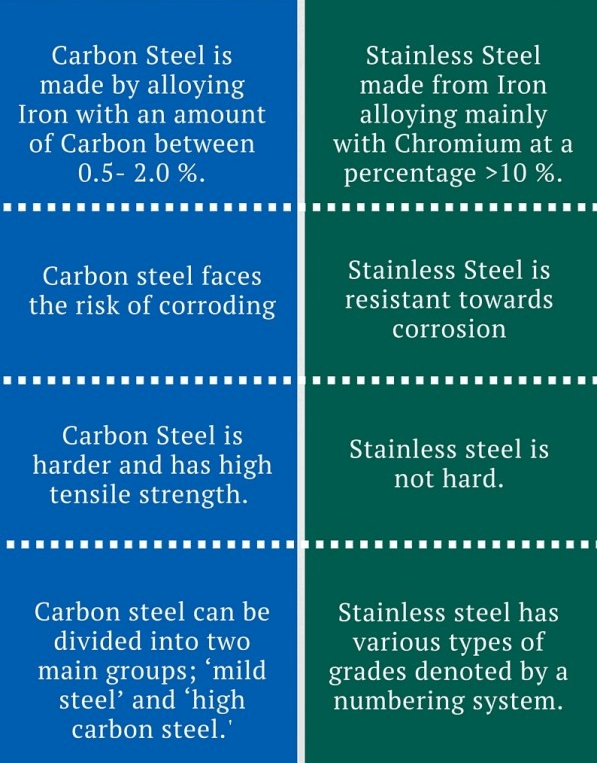

Carbon steel vs stainless steel have the same basic ingredients of iron and carbon. Their main difference is alloy content—carbon steel has under 10.5 percent alloy content, while chrome steel must contain 10.5 percent chromium or more. That essential difference is what gives carbon steel and stainless steel their distinct physical and chemical characteristics.

Contents

The General Steel Composition

Two essential elements of steel are iron and carbon. Generally, steels with more carbon content are hard and brittle, while steels with a lower carbon content are ductile and hard.

Of course, it’s rarely that pure. Alloying elements like chromium, molybdenum, nickel, manganese, or silicon are often added to extend corrosion resistance or attain a far better balance between strength and toughness.

What is Carbon Steel?

Simply put, carbon steel, by definition, is very simple. It is simply iron with some carbon and limited alloying elements. Carbon steel consists of iron and 0.12 – 2.00 percent carbon. The broader definition includes alloy steels, which may also contain up to 10.5 percent alloy content. Even within the confines of under two percentage points of carbon, there’s a huge variance in physical characteristics—especially hardness.

When people mention carbon steel, they’re usually pertaining to the high steel utilized in making knives and tools.

Within the carbon steel definition, materials are often defined as either low carbon steel or high-carbon steel. Low-carbon steels are extremely common, while high-carbon steels are only utilized in high-strength, non-corrosive environments.

High carbon steels are very hard, which makes them good at resisting abrasion and retaining their original shape and design. They will withstand significant force before deforming. Unfortunately, hard metals also are brittle: when placed under extreme tensile stress, high carbon steels are more likely to crack than bend.

Low carbon steels are more common than high carbon due to several reasons, including; lower production costs, greater ductility, and simple use in manufacturing.

Low carbon steels tend to deform under stress rather than breaking, which ductility makes low carbon steels easy to machine and weld. They’re frequently utilized in automobile body panels, bolts, fixtures, seamless tubes, and plate.

What is Stainless Steel?

Stainless steel contains iron, carbon, and a minimum of 10.5% chromium content. The chromium is key—it reacts with oxygen to make a passive layer that protects the steel from corrosion.

That protection reduces the likelihood of chrome steel rusting—important for outdoor site furnishings, like bollards installed in wet environments. The higher the chromium content, the higher the corrosion resistance.

Stainless steels are united around one key material property: excellent corrosion resistance due to high Chromium content (>10.5% by mass) and low carbon content. Beyond corrosion resistance, the mechanical properties of those steels can vary greatly.

Austenitic chrome steel is the most common sort of stainless steel. They are corrosion resistant and can be easily machined and welded, though they can’t be heat treated. 303 and 304 are the foremost common types of austenitic stainless steels, and 316L may be a variant that maximizes corrosion resistance. These steels are utilized in a wide range of operations — because they’re weatherproof, they work almost anywhere.

It’s important to be careful with the stainless steel grade when purchasing appliances and other big-ticket items. Not all steels are created equal. Stainless steel with a minimum 10.5% chromium content is far cheaper and less durable than one with 16%, and therefore the difference will show in maintenance costs and repair life.

Areas of Difference: Carbon Steel vs Stainless Steel

There are five key areas of difference between stainless steel vs carbon steel. These are;

- Corrosion Resistance

- Mechanical Properties

- Appearance

- Cost

Let’s look at each of these areas individually.

1. Corrosion Resistance

The most obvious difference between carbon steels and stainless steels is the ability to resist corrosion.

Stainless steels, because the name implies, are generally the more corrosion resistant of the two types of steel. Both carbon steel and stainless steels contain a significant amount of iron, which oxidizes when exposed to the environment, creating rust.

The added chromium in stainless steel makes it more corrosion resistant than carbon steels. The chromium will combine oxygen more readily than iron. When the chromium attaches to the oxygen, it creates a chromium oxide layer that protects the remainder of the material from degradation and corrosion.

Carbon steel doesn’t typically have enough chromium to make this chromium oxide layer, allowing oxygen to bond with the iron which ends up in iron oxide, or rust. So if corrosion resistance may be a key factor, stainless steel is the better option than carbon steel.

2. Appearance

If the work requires an aesthetic appeal, the looks of the metal must be considered. Stainless steels with particular finishes are generally preferred when cosmetic appearance may be a factor.

Although both are often sanded and polished to possess a bright, shiny look, steel requires a transparent coat or paint rather quickly after the polishing process. If it’s not applied, the steel will begin to tarnish and eventually rust.

Also, if the stainless steel is scratched, it’ll retain its luster within the scratched area, while a painted piece of carbon steel would wish to be repainted or it’ll be subject to corrosion.

3. Cost

Which is cheaper between steel vs. stainless steel? Another important consideration is that the cost difference between carbon steels and stainless steels. Although different grades have varying costs, stainless steels are generally costlier than carbon steels.

This is often due mostly to the addition of a spread of alloying elements in chrome steel, including chromium, nickel, manganese, etc. These additional factors result in a higher cost than carbon steels.

Carbon steel, on the other hand, is usually composed of relatively affordable iron and carbon elements. If you’re working with a decent budget on your next project, steel could be the most straightforward option.

4. Mechanical Properties

It is difficult to form sweeping statements about the differences in mechanical properties between carbon steels and stainless steels due to the various different types and grades in each type of metal.

Stainless steels are often more ductile than carbon steels because they typically have higher amounts of nickel. However, this does not negate the fact that there are very brittle grades of stainless steel. One example is martensitic grades.

Carbon steels with very low amounts of carbon might not match the tensile strengths of some stainless steel because of the alloying elements that most stainless steel grades contain, which increase its strength. However, if there’s enough carbon (typically a minimum of 0.30% by weight) within the steel, it’s more readily heat treated than austenitic stainless steel.

From these differences, I hope that you can easily tell which steel will perfectly suit your application.

Carbon Steel vs Stainless Steel: Final Verdict

The debate of carbon steel vs. stainless steel may be a bit more complicated than originally thought, as steel can ask two differing types of steel: traditional carbon steel and low-alloy steel.

Compared to the low carbon steel, chrome steel offers a huge upgrade in strength, hardness, and, most significantly, corrosion resistance.

High carbon steel, on the other hand, offers strength rivaling and sometimes exceeding stainless steel but is essentially a distinct segment material within the manufacturing world.

Unlike any carbon steel, chrome steel can survive and thrive, oxidation free, in corrosive or humid environments. That being said, carbon steel is far cheaper than stainless steel and better fitted to large structural components, like tubes, beams, and rolled sheet steel.

Low-alloy steel is superior to steel in most ways, but still lacks corrosion resistance. It can effectively match the fabric properties of stainless steel — as a result, alloys like 4140 and 4340 are often machined and utilized in many applications during which touch oxidation doesn’t hurt.

Stainless steel may be a higher grade material better utilized in industrial operations, where part quality can’t be compromised.

Carbon Steel and Stainless Steel for 3D Printing in China

Whether you want to use carbon or stainless for making products, it is vital that you choose the right steel fabricator. At Roche Industry, we provide 3D printing for carbon and stainless steel.

All you need is to send 3D designs of the products that you would like to create. Our designers and engineers will get down into the business of actualizing your dream.

Related source links:

18/10 stainless steel VS 18/8 stainless steel: What Are the Differences

Aluminum vs Stainless steel: What are the Differences?

304 vs. 316 stainless steel: What are the Differences?

Titanium vs steel: what are the differences?

420 Stainless Steel vs 430 Stainless Steel: What is the Difference?

Surgical Steel vs Stainless Steel: What are the Differences?

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.