Fused Deposition Modeling (FDM) is a technique used in additive manufacturing. The developers use it for making functional parts as well as constructing prototypes.

Many designers use FDM in research and developing when they want to improve on the processes. They will develop new materials and apply them to the engineering processes.

That said, what is fused deposition modeling? It is a technique of additive manufacturing where you fuse layers in a particular pattern to create the object. You will melt the materials beyond its glass transition temperature.

After that, there will be an extrusion process that will create the object layer upon the player.

Contents

History of FDM

The fused deposition modeling is a famous method that designers have been using to create prototypes since the 1980s. The technology is among the fastest and most cost-effective way of creating consumer goods.

Scott Crump invented this technology in the 1980s. Since then, other 3D printing organizations adopted the same FDM technology under different tags. You can involve it in the making of various parts and objects.

How does Fused Deposition Modeling work?

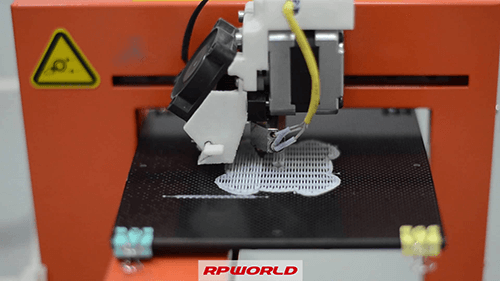

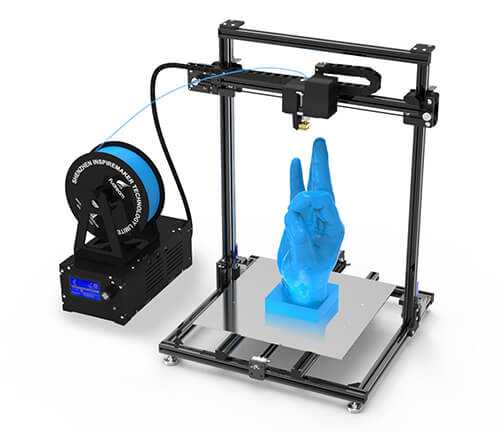

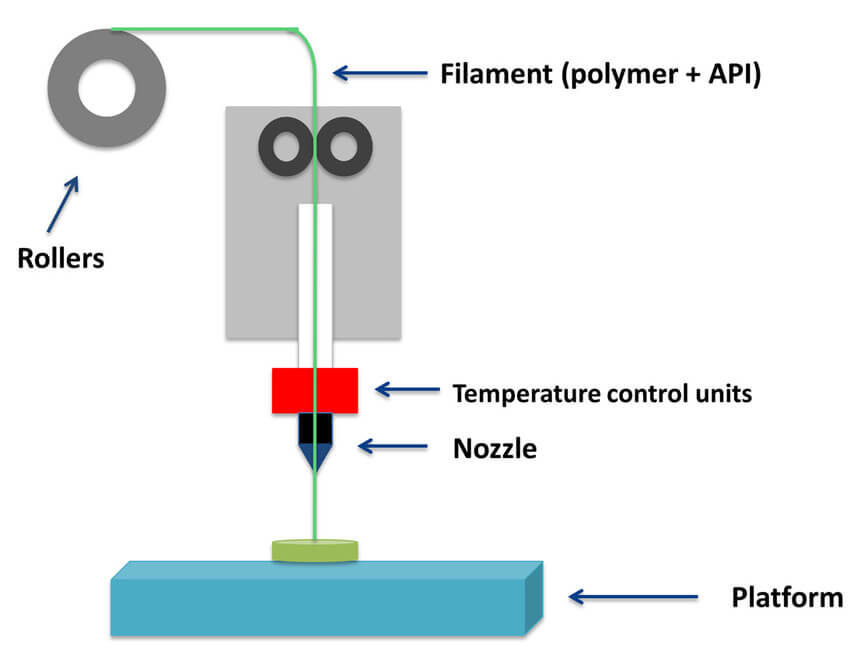

It is the basic 3D printing technique, which includes three primary parts. It has a printing plate where you will print your part. It also has a filament coil, which acts as a printing material. Last but not least, there is an extrusion head, which we refer to as an extruder.

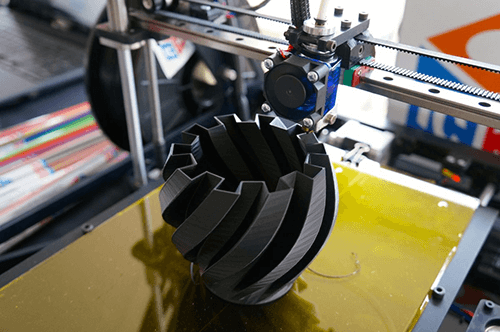

You will begin by melting the filament by the printer’s extruder. It will eventually deposit the material layer upon layer on the plate. You will be using 3D CAD software in the modeling process. Such software may be SelfCAD or TinkerCAD.

Once you design, the 3D model will split into various layers through slicers before choosing the printing parameters. As the printer attains optimal temperature, which is around 200 degrees Celsius, the 3D printer will start the printing process.

The required temperature is ideal for melting your material, such as ABS (Acrylonitrile butadiene styrene) or PLA (Polylactic acid).

As it gains the required temperature, you will extrude a 1.75mm diameter filament onto the platform. It will move past the nozzle on X, Y, and Z axes. The platform will begin to descent the next layer until the object gets printed.

During the printing process, the entire process undergoes the support of scaffolds. These scaffolds will aid the model’s hanging parts, which are likely to collapse

Furthermore, the scaffolds may come from similar materials as the object. Alternatively, the material may be soluble in limonene or water.

The most complicated 3D printers come with various extruders to combine multiple colors or support materials.

Fused deposition modeling printers will involve two types of materials. They are either support materials or modeling materials. The support materials will act as scaffolding, meant to support the object which will be undergoing the printing process.

As you start the printing, the materials will take the form of filaments or plastic threads that you unwind from the coil. Consequently, they get fed via an extrusion nozzle.

As a result, the nozzle will melt this filament and eventually extrude them to onto a base, which is either a table or a building platform.

You will use the computer to control the base and the nozzle. Typically, the extrusion nozzle will be moving over the build platform either vertically or horizontally. The thin layer of plastic will begin to cool and harden as it binds to the beneath layers.

As you complete the later, lower the base by a sixteenth of the inch to give a room for the subsequent plastic layer. The size of the object that you will be manufacturing will determine the printing time.

The process of printing a smaller object is faster than the big ones. Above all, the fused deposition modeling process is slow when compared to other techniques like selective laser sintering.

Removing Support

As you remove the object out of the printer, you must also remove the support materials. You can do so by soaking the object in a detergent solution or water.

You can use your hand to snap the support materials if it has thermoplastic supports. This method will risk damaging the print. As if that is not over, you can still sand the object or paint it to enhance its appearance.

Minimizing Warping

One of the aspects that you ought to be careful about is warping. The parts may likely warp since they cool at a different time to create tension. Concerning that, the sections of the printed model will begin to contract and shrink. It will later affect the surface finish and print quality.

You can minimize such a scenario with an excellent heated bed and adhesion. It will help in anchoring the part down, thereby reducing warping and stress.

The most advanced FDM printers have a controlled printing environment to reduce the chances of warping. These printers allow the user to alter the temperature and humidity that will suit the process and prevent warping. Precisely, the slow cooling process will prevent the warping process.

Application of Fused Deposition Modeling

Fused deposition modeling is a widespread technique among various automotive producing companies. They involve the FDM in their product development, performing prototyping, and manufacturing processes.

You can still use the FDM process in the product of end-use parts. Some of the thermoplastics are suitable for making drug and food packaging. It is a popular printing technique in the medical industry. The good news is that most of the FDM printers are affordable.

FDM at Home

There are models out there that are user-friendly. The manufacturer designed them with small scale business owners in mind to make fused deposition modeling products. They will perfectly fit do-it-yourselfers (DIY). Since there 3D printing machines are least expensive, you can easily afford them to work from home.

However, you should do proper research before landing the ideal product for home use. Since technology is ever-improving, you can still get better models to serve you efficiently.

How to Choose the Right Printing Parameters in FDM

The printing parameters will affect the speed of the print, strength, quality, and surface finish. You can optimize the following areas to get the desired results.

· Print Speed

To some users, fused deposition modeling machine seems to be a slow process. Indeed, you should be cautious of over-speeding your printer as it may bring various errors. The notable example may be collapsed parts or corners falling in.

Most importantly, it compromises the surface finish and the overall quality. You set the printer rightly to get the most admirable features.

· Layer Height

Lower layer height will translate into a smoother printer. Here, the printing process will be lower. But that is not all. You can still use large layers of heights and increase the printer’s speed without encountering diverse effects. After all, it also depends on the object you will be printing.

You should use the lowest layer if you are printing and an intricate object like the face. On the contrary, you print an object like a big cube; you will be at liberty to use big layers. Furthermore, you will easily print it without encountering a drop in quality.

· Nozzle Diameter

The diameter is critical in determining how you will be printing. The most common diameter of the nozzle is around 0.4 mm. Anything that may be below such a measurement can be challenging to print.

You can check the nozzle that you may be having on the printer and optimize it to the right diameter. If you want to encounter smoother surface areas, then use smaller nozzle diameters. Unfortunately, you will take a bit longer to print a lower layer height.

· Infill

You cannot FDM print parts in a solid-state. The usual process is to use a 20% infill to create sturdy parts from SLA, thereby saving time and money. If your needs are only to create a rough prototype, you will only need a 20% infill.

In exceptional situations, you may need to attain a sturdy model. Basing on that, you can use 80% infill.

Printing Supports

You will need supports to hold the part that overhangs. The design will prevent the part from falling and eventually deforming. You may need dual extruders printers that are suitable in this case. They will print the supports in dissolvable filament like PVA or HIPS.

FDM Printer Performance

The fused deposition modelling 3D printers are affordable, but still, they have some shortcomings. Firstly, they are slow. Large prints can take up to 12 hours to have the right output. In case you want to achieve a super speed with an FDM printer, you instead consider SLS or SLA.

The best FDM printer will be accurate while performing at 50 microns. The quality at this level will be high, although not excellent. When compared to other printing technologies like Binder jetting, the latter produces higher quality and precision.

Factors to Consider When buying a 3D FDM Printer

Fused deposition modeling (FDM) technology revolutionizing the word by a great deal. They are available and easy to operate. These printers are of high demand from hobbyists to dentists, engineers, and jewelers. However, not every available FDM printer is suitable for every user.

Buying the right printer will require some particular tips from the related field. You should avoid making hasty decisions without cross-checking your ideal 3D printer with some aspects as discussed below:

1. Application

You need to understand the purpose of that particular 3D printer. Some individuals may be for hobby purposes, industrial prototyping, household use, and more. For you to have a successful printing experience, you must define your goals.

After knowing what you want to print, for example, those printers for industrial-scale production parts are different from those 3D printing gadgets at the comfort of your desktop. You will also need to know the frequency of your printing.

2. Material Application

The fused deposition modeling 3D printer must be compatible with the right material that you will be used to create an output. The used materials should have the correct properties to perform as per the specification.

The frequently used material is Acrylonitrile Butadiene Styrene (ABS). It is popular thermoplastics that companies use to make consumer goods. Along with that, some industries use other thermoplastics like PC (Polycarbonate). Here, the support materials are either brittle plastic or water-soluble wax.

One great advantage of thermoplastics is that it endures chemicals, mechanical stress, and heat. You can use it to make the prototypes that will withstand testing. FDM process will allow one to print various details needed by engineers in testing parts for fit and form.

For instance, those materials used for FDM technology should serve you correctly in the production of the needed parts. You should, therefore, know the correct materials that you will employ in making your final output.

3. Build Volume

The build volume talks about printing space. You should buy the right printer that allows the average products to get printed. It can be unreasonable to settle for the large printer that will accommodate all sizes. It will call for the increased printing costs and compromise the quality of smaller delicate prints.

You can involve large printers by outsourcing the services if you require them in fewer numbers.

4. Availability and the Cost of the Materials

The material properties should favor fused deposition modeling costs. For instance, the ABS material is a sturdy plastic that will require a considerable amount of heat. It will work best when it has an enclosed 3D printer in maintaining the right temperature.

However, you can involve this filament only when the room is under proper ventilation. ABS is the right material to use when considering outdoor printing.

5. Resolution

Resolution plays a crucial role in the determination of printing tiny features. It also determines the finishing of the printed object. If you want to print the tiniest features, then settle for that printer that has a high resolution.

For our case, the layer height will be thinner, resulting in a smoother surface finish. In the long run, the fused deposition modeling (FDM) 3D printer that has high resolution will be beneficial to your enterprises as it improves quality. The best FMD printers have 100 microns.

6. Slicing Software

Some FDM printers come with their slicing software right away form the manufactures. The good news is that this software is compatible with the printer hence offering you the best results.

If you lack the proprietary software, you will depend on free slicing software. The downside of such software is that the calibration may not suit that specific FDM 3D printer. You should look for the right brand that will come with the appropriate software to handle your tasks.

The FDM should have a quality and user-friendly interface. The advanced models come with a touchscreen UI, which is simple and easy to navigate.

7. Safety features

Do you know that it is difficult to be extremely safe while working with electric appliances? You should keep an eye on some of the safety features that will enhance your 3D printing experience.

A perfect example is an automatic nozzle cooling as you complete the printing process. Suppose your printer has a heated bed, get a feature that will automatically put it off when you complete the printing task.

8. Axis Adjustability

You should fine-tune your printer by loosening or tightening the tension on the three fundamental axes. The right fused deposition modeling (FDM) 3D printer should have an easy to access belt tension adjustment. The design will be time-saving when making some adjustments.

9. Pricing

Well, most of the FDM printers are affordable. However, you should look for the underlying features that will support your artistic work. You need to perform enough research to come up with the right product that suits your needs.

Read the reviews from online platforms about particular brands and come out with the resolution. The advanced FDM machines will come with slightly higher prices. Choose the famous brand that gives a more extended warranty period as prove to their quality.

Advantages of Fused Deposition Modeling

a) Reduced Costs

FDM technology is a popular technique that many companies use since it is user friendly and has reduced costs. Companies should know that while producing items that involve FDM technology happens to be cost-effective than using a traditional manufacturing method.

For instance, the materials powder that you use in other processes like SLA or SLS is costly. On the contrary, the critical material that you use in FDM technology like the filament is much lower. As a result, FDM technology will become attractive to several companies.

b) The broad range in Materials

The range of filament is broad-based; hence various companies can change the materials easily since it is economical. Other companies can decide to process various types of materials simultaneously. As such, one can achieve in printing complex models.

You may need new print heads in supporting certain materials like PVA and HIPS. It also allows you to print while using multiple colors.

c) Accessibility

The fused deposition modeling process happens to be more accessible than other 3D printing methods. By practice, many people will settle for this technique since it is fast and easy to operate. It can be an ideal option for various companies that lack 3D experience.

It also favors those organizations that have a 3D experience. You can easily create any item as long as it is in the CAD file. The entire process is under the management of the machine.

d) Less Time Consuming

It may not need other post-processing when compared with other tech techniques. For instance, you will not have to knock off powders or get careful with costly liquids. In other words, the process will not need any post-processing. The product remains ready for use.

e) Accuracy

The user will enjoy a high level of accuracy since the output is highly accurate. It can still print finer details with precision. As such, you can involve it in making a sophisticated design that requires more exceptional details.

The process is accurate since even within 0.005 inches.

FDM Limitations

The quality of the print may not be as good as that of SLS or SLA.

The fused deposition modeling process is slightly slow. Some industries may not adopt it if they need high product numbers that they may require quickly.

The process of layer by layer printing may result in warping or minor shrinking.

Types of FDM 3D Printer

There are four types of FDM 3D printer. They are as follows:

1. Delta FDM 3D Printer

They have a circular print bed featuring a 3D print extruder with three fixed triangular points. All these print points can move downwards or upwards within the cylinder structure.

2. Cartesian Printer

They are the most accurate printers having better print quality. However, they may be slower when compared to other options like Delta 3D printers.

3. Polar 3D Printers

Such printers happen to have similar features to Cartesian printers. The only difference is they use polar coordinate systems. Furthermore, they have rotating print beds alongside the print heads.

4. Robotic Arm 3D Printer

It is the cool-looking printer type. One of its advantages is flexibility when printing. Furthermore, this printer is mobile and versatile. You can use it to print the geometrically complex.

You can use it to print large items. However, it has a challenge in printing small intricate parts since it will compromise the quality issue.

Wrapping Up

Are you a 3D enthusiast? Indeed technology is ever-evolving to enhance your 3D printing experience. Fused deposition modeling happens to be among the best techniques that various consumers use in the manufacturing of parts.

You can take advantage of its affordability and make various objects to meet your needs. They are versatile and accurate; hence you can involve them in printing high-quality objects. The process of printing is rather straightforward.

You can improve your 3D printing experience by making use of FDM technology. You will get the right output that makes you withstand competition from the market. Make a lifelong decision by utilizing such machines in your work.

For more services on the Fused Deposition Model, call us for more details.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.