Perhaps you know it, maybe you don’t. However, Stereolithography (SLA) 3D printing is increasingly becoming a popular form of rapid prototyping due to its ability to produce highly precise, isotopic, and watertight parts. In this ultimate guide to SLA rapid prototyping, you will learn how SLA printing works, and the benefits of using SLA rapid prototyping.

Contents

Introduction

Technological advancements in 3D printing have continued to change the way many people are approaching prototyping and 3D productions. 3D printing is helping experts across all industries to cut costs related to outsourcing, iterate more quickly, and enhance more production processes.

Stereolithography 3D printing has undergone rapid changes. Convectional resin 3D printers have come more monolithic and less cost-effective. In contrast, the current market situation has format desktop printers that can produce industrial-quality parts at more affordable prices.

What is SLA 3D Printing?

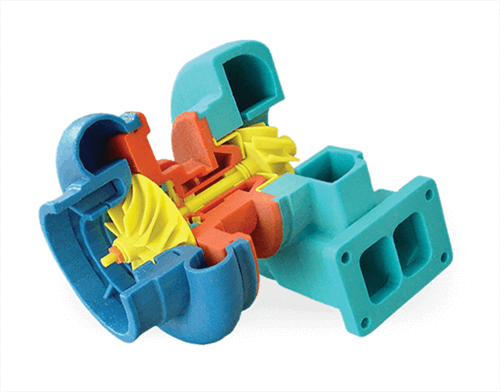

SLA is part of a family of additive manufacturing technologies popularly known as vat photopolymerization or resin 3D printing. These types of machines work using the same technology and principle that incorporate laser or projector as light sources to cure resin into a hard form of plastics. The main difference that can be noted is in the arrangement of the primary components, such as the resin tank, light sources, and the platform of the build.

SLA 3D printers work by using light-reactive thermoset objects (resin). Short molecular chains are joined by exposing SLA resin to specific wavelengths of light. This process leads to polymerization of monomers and oligomers into solid geometries that can either be rigid or flexible.

SLA printed parts possess the highest accuracy and resolution, precise and sharp details, and the most delicate finish compared to the rest of 3D printing technologies. Additionally, the main advantage of SLA 3D printing is its versatility.

Manufacturers of materials using SLA 3D printing have in the past formulated innovative resin designs with various optical, mechanical, and thermal specifications that match those of high-end industrial thermoplastics.

Why Choose SLA 3D Printing? The Benefits of SLA Rapid Prototyping

Engineers, manufacturers, and many other professionals prefer SLA 3D printing because of its exceptional features, quality surface finish, precision, and accuracy, as well as other mechanical characteristics like water tightness, isotropy, and versatility.

Isotropy

3D printing creates parts a layer at a time. This process makes the completed components have variations in strength according to the orientation of these parts and different properties in all the dimensions of the created material.

FDM vs. SLA 3D printing

Printing processes that are based on extrusion, such as fused deposition modeling (FDM), are mostly anisotropic since the printing process creates layer- to-layer variations. Such properties (anisotropy) limit the effectiveness of the FDM models in various applications. Additionally, this feature may require adjustments on the geometry side of the part to compensate for the drawback.

On the other hand, SLA resin printers create highly isotropic parts. Achieving this feature depends on various factors that can be controlled through the integration of material chemistry and the printing process. In the process of SLA 3D printing, resin elements form covalent bonds. However, the layer to layer part remains in a semi-reacted green state. While in this state, the resin components retain polymerizable units that can be joined across layers by covalent bonds. This process imparts isotropy and watertight feature to the created material.

However, there are no variations in the three dimensions of the part on the molecular level. As a result, the pieces come in a predictable mechanical performance that is useful in various applications like functional prototyping, end-use components, and fixtures.

Watertightness

All materials printed using SLA rapid prototyping technology are continuous. This feature creates waterproof objects that are essential for engineering and manufacturing applications that need controlling of air or fluid flow. Air and liquid flow challenges can be easily eliminated using this property, and the resulting objects are essential for use in automotive, biomedical studies, and consumer products such as kitchenware.

Accuracy and Precision

SLA 3D printing creates accurate and precise components that are suitable for various industries like dental and manufacturing, among others. Multiple factors must be controlled tightly for such accuracy and precision to be achieved.

SLA 3D printing can be said to be somewhere between standard machining and fine machining in terms of accuracy. SLA is the most commercially tolerant of all the 3D printing technologies.

The accuracy and precision achieved on parts printed by SLA also depend on the characteristics of the original material.

Fine Features and Smooth Surface Finish

SLA 3D printing is considered to be the gold standard when it comes to quality and smooth surface finish. The appearance of SA-printed parts can be compared to conventional manufacturing processes like machining, injection molding, and extrusion.

The surface quality produced through SLA rapid prototyping is suitable for applications that require a flawless finish. For instance, end-materials like spoon ends and shaving razor handles such as used by Gillette are some areas where this feature is utilized.

Material Versatility

SLA resins can be formulated in a wide range of configurations. In other words, the designed parts can either be soft or hard, filled with secondary materials such as glass and ceramic or with mechanical properties such as heat deflection or resistance to impact. In other words, parts created by SLA 3D printing can come with opposing features based on the settings of the printer to meet the desired state.

These materials can range from industrial-related, such as dentures to ones that match final components for printing and are formulated for endurance and performance under the most adverse conditions.

Final words

In various cases, the combination of versatility and functionality become the most appealing aspect of SLA rapid prototyping (3D printing) to many manufacturers and businesses. After identifying that a particularly functional material can solve one application, more possibilities are often established. Through SLA 3D printing, professionals can leverage the diverse capabilities of various materials. The multiple benefits of using SLA 3D printing makes it stand out among other 3D printing technologies. Lastly, by any chance you require SLA Rapid Prototyping services, contact us.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.