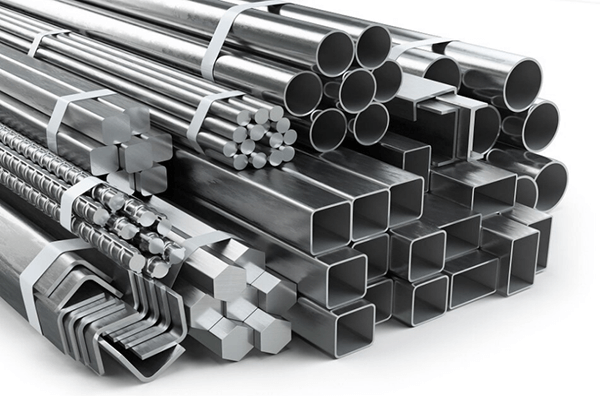

Take an in-depth look at the surface of stainless steel. To the eye, your material may look smooth and consistent. But the reality all comes right down to the chrome steel finish.

From mill finishes to applied finishes, the stainless steel finishes that are applied to the surface of your stainless steel can play a much more significant role than you’ll realize.

Contents

What is Stainless Steel Finishes?

Stainless steel finishing is an all-encompassing term wont to describe the method of placing some sort of steel coating on the surface of stainless steel metal, typically mentioned as a substrate.

It also can involve the implementation of a process for cleaning, polishing, or otherwise improving a surface. Stainless steel finishing often consists of electroplating, which is that the process of depositing metal ions onto a substrate via an electrical current.

While some products may only require standard stainless steel finishes, others may have something extra to enhance surface appearances, improve environmental performance, or maybe reduce safety concerns.

But when it involves stainless steel finishes. Which level means your metal is actually finished? That answer is ultimately up to you and the specifications you define for your project.

Read on as we explore different types of stainless steel finishes. At the end of this guide, you will be in a perfect position to choose the best finishes.

Benefits of Stainless Steel Finishing

Probably you are wondering whether stainless steel finishes are of any importance. Are they worth the investment?

The fact is stainless steel finishes are critical and deserve your full attention.

There are several advantages of stainless steel finishes which include;

Corrosion resistance of stainless steel: There is no doubt that stainless is known for having high resistance to corrosion. The presence of the finishes just enhances the resistant nature of stainless steel.

Improves the temperature properties: The finishes can either increase or reduce the temperature resistance of the stainless steel. The finishes also make the steel less susceptible to external temperature changes.

Ease of fabrication: The stainless steel fishes ensure that this metal can be easily cut and welded into its respective application area.

Aesthetic value: This is one of the main reasons for stainless steel surface treatment. It can improve the overall appearance of the stainless steel from a dull piece of metal to an extremely attractive piece of metal.

Increases strength: It is imperative to note that some finishes have a direct impact on the steel structure. They make the stainless steel stronger so that it can be used for different applications.

Hygiene factor: Some stainless steel types such as surgical stainless steel are required to maintain the highest levels of hygiene. Some stainless finishes types make it easy for you to clean the metal.

As you can see, these benefits cannot be easily ignored. Once you buy the raw stainless steel, you should choose the finishing that you think will be perfect.

Types of Stainless Steel Finishes

Not all the stainless finishes are the same. They come in different types. Let’s look at the types of stainless finishes that you can choose from;

Mill Finishes Mill finishes forming the basic finishes for all the products that are made of flat stainless steel materials. This finishing is applicable, whether it is hot rolled or cold-rolled stainless steel. Although the mill is mainly used for the building components, they also provide surface finishes for stainless steel.

Mill finishes to provide protection against corrosion. They also protect the stainless steel from acids and other chemicals.

There are four main types of mill finishes. These are 1D, 2D 2B, and 2R.

1D Stainless steel finishing: This finishing is mainly used on the thick metal sheet plates. It is quite dull and not as shiny as other finishes. This explains why it is not an ideal finishing for decorative purposes.

It is an ideal finishing for those major industrial steels where looks are not a priority.

2D Stainless steel: This type of finishing appears to be more refined than the 1D finishing. It is created by cold rolling and heat treatment. 2D finishing is capable of creating some level of reflection on the surface of the stainless steel. For this reason, it can be used for aesthetic use.

2B stainless steel finishing: This is created in a similar manner to the 2D only that a light rolling is used to give the steel surface a polished finishing. The method forms a foundation for the brushed and glossy finishes.

2R Finishes: Here, a cold rolling technique is used for polishing the surface of the stainless steel. It is very reflective and has an exceedingly high aesthetic value. It is also hygiene-friendly since it cannot host contaminants as compared to other steel finishes.

Mechanically polished and brushed finishes

When it comes to stainless steel finishes, you need to be careful with the procedure in which you work with them. By this, we simply mean the foundational finishing to the surface finishing. It is at this point that the mechanical polishing and brushed finishes come in.

Mechanically polished and brushed finishes entail the use of very abrasive materials that penetrate through the surface of the steel. It encompasses various processes such as grinding, buffing, polishing, and brushing the surface of the stainless steel.

The mechanical-inspired finishes can either be unidirectional or multi-directional depending on how you would like your steel to appear. This finishing will also have a direct impact on the texture of the stainless steel material.

Mechanically polished finishes can entail the use of wet oil emery or even dry fiber. brushes. These options boast of having high luster, low degree of roughness, and a sheen finishing.

The brushes are used to achieve the uniformity on the surface of the metal.

The wet oil finishing results to a smoother surface than the dry finishing. However, it is more expensive.

With these two stainless finishes, it is vital that you agree with the contractor before they start working on stainless steel. Most stainless steel manufacturers give samples so that you can have an easy time choosing.

Some types of mechanically polished finishing include;

2J: This stainless steel surface is achieved by polishing and brushing the steel in a unidirectional pattern. It ends up creating a non-reflective finishing.

2K: This finishing creates a smooth and reflective surface that is suitable for architectural applications. Finer grit belts are used to create finishing with a minimum level of thickness.

2G: This is a uniform uni-directional finishing that has some moderate level of reflectivity. It is ideal for internal applications.

2P: This finishing has high levels of reflection and is super smooth. A soft cloth is used for buffing the surface until it achieves the desired smoothness.

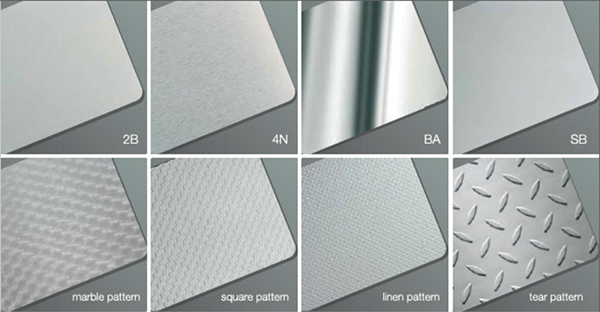

Patterned finishes for stainless steel

Some stainless steel metals are known for having different distinct patterns. These are finishes that are achieved using different patterned rolls which stiffen the stainless steel.

These finishes are ideal on flat stainless steel sheets and can do a pretty good job of creating some desirable visual impressions.

There are two main types of patterned finishes for stainless steel. These are 1-sided pattern and 2-sided pattern. The 1-sided pattern can be classified as 2M< while the 2-sided pattern is classified as 2W.

Patterned finishes for stainless steel are the best solutions for applications where the steel is likely to suffer some physical damage. They do a commendable job in concealing those deformations.

Such application areas include airport terminals, building entrances, factories among others. You can choose unique patterns in case you want to enhance the aesthetic value of the steel.

Bead blasted finishes for stainless steel

Bead blasting finishing is ideal for creating a uniform, low-reflective, and non-directional surface on the stainless steel metal. It can achieve a visually appealing finishing that can play a decorative role.

Blasting can be achieved using different types of materials which include ceramic beads, steel particles, grounded nutshells, aluminum particles, glass among others. Carbon steel or even conventional iron should not be used for this finishing process as they can cause severe contamination.

The finishing created will vary depending on the blasting force and the blasting material that is used. It is critical to seek advice from the manufacturer before you proceed with this method of stainless steel finishing.

Electro-polished finishes for stainless steel

This is a steel finishing method that is used for a wide range of commercial applications. It is applicable for steel sheet and shaped stainless steel.

Electro-polished finishing works by removing the troughs and peaks from the surface of the steel resulting in a smooth surface finishing. The final outcome will depend on the finishes that were used initially.

Electropolishing also plays a protective role as it results in increased corrosion-resistance of the steel.

Conclusion

At this point, you know different types of stainless finishes and the impact that they have on the steel. You can now differentiate the different types of stainless steel finishes and choose one that will suit your needs. For more information about stainless steel finishes contact Roche Industry for advice.

Related source links:

Everything You Should Know About Stainless Steel Grades

Everything You Should Know About Stainless Steel Sheet Metal

Everything you should know about stainless steel mesh

Handbook: The Complete Guide To Steel Gauge Chart

Read more

https://www.assda.asn.au/benefits-of-stainless-steel

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.