Well, manufacturing is a concept that is taking shape in our lives. Sometimes back, it was next to impossible to manufacture something at home. One had to rely on a particular company to get the finished product.

Nowadays, the reality of manufacturing has changed in approach. One can buy a machine and a computer to manufacture certain aspects in the house. The included software will allow you to construct anything of your imagination.

Some of the things you can manufacture in the comfort of your home could cost millions of dollars to get produced in a company. So, what is causing this giant leap in the manufacturing industry?

We will be exploring some of the answers to this question—let’s begin.

Contents

Additive Manufacturing

Additive manufacturing is the latest concept, which is also known as 3D printing. It uses technologies that will add an increased layer by layer of your material until the product becomes ready.

In additive manufacturing, you begin with completely nothing. Along the process, you will be adding what you need. Some of the materials you could be using are plastics, concrete, and metal. Surprisingly, other materials may be human tissue.

For one to successfully 3D print, he may need the following items:

- 3D print software (Computer-aided design software-CAD)

- A computer

- 3D printing machine

- Materials

Typically, 3D printing is a unique concept that works differently on particular elements. For example, you will not 3D Titanium in a similar manner you will do on plastic materials. They will differ in terms of properties.

So, how do you begin to 3D print? Well, you must sketch the design by using Computer-Aided Design software. As the machine reads the sketch, it will start to lay down layer upon layer of the material. Before long, it will convert the material into a 3D object.

3D happens to be the most common method of additive printing. The cool thing is that it will combine with other technologies such as direct digital manufacturing, rapid manufacturing, and layered manufacturing, among others.

Additive Manufacturing Materials

There are several materials that one can put to use while creating 3D objects. The AM (Additive Manufacturing) technology makes engine parts from the alloys. Some of the material that this technology uses are:

1. Metals

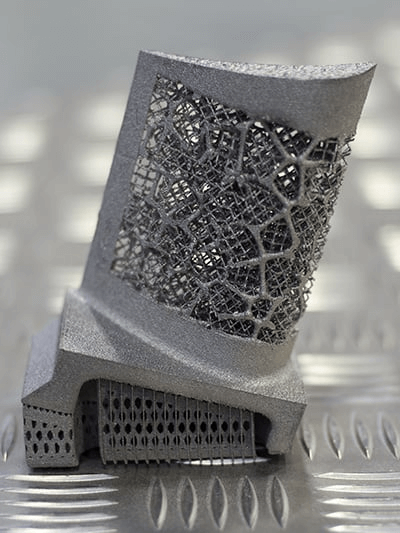

Additive manufacturing (AM) uses metals and other alloys to create various objects. It can use precious metals like silver and gold. Or even better, it will use some durable metals like stainless steel and Titanium.

2. Thermoplastics

They are the most widely used materials in additive manufacturing. We can classify them as follows:

- Acrylonitrile butadiene styrene (ABS)

- Polylactic acid (PLA)

- Polycarbonate (PC)

You can use them to create a product for daily use.

3. Ceramics

Several types of ceramics can manufacture different items. Some examples of ceramics to use are:

- Tricalcium phosphate

- Zirconia

- Alumina

Most of its application revolves around utensils like glass products

4. Biochemical

You can use biochemical in healthcare applications, such as supporting bone structures. The widely used material in such an area is calcium phosphate, silicon, and zinc.

Processes in Additive Manufacturing

There are multiple processes that you may use in additive manufacturing. They are as follows:

1. Material Extrusion

The method is standard around the world. It involves extruding spooled polymers. Alternatively, they draw them via a heated nozzle, mounted on the moving arm. The bed will move vertically as the nozzle moves horizontally. Consequently, the melted materials will get built, layer upon layer.

2. Directed Energy Deposition

The process happens to be similar to the material extrusion one. One significant advantage is that you can use it with more comprehensive options of materials like ceramics, polymers, and metals.

3. Material Jetting

Material jetting will use a print head in the same way an inkjet printer does. The head will create a 3D object by moving x, y, and z axes. The layers will require adequate time to cool and harden. The good news is that you can cure them by using ultraviolet light.

3D Printing Technologies

- Fused deposition Modelling (FDM)

FDM is the most popular 3D technology. Also, the process is rather simple. The machine will use heat to melt a filament. Later, it will use a printer’s head to deposit it layer upon layer. The technology is less expensive and easy to use.

Unfortunately, it is not a commonly used method in the industrial world as it creates substandard products. Specifically, they are both less precise and robust. Some of the widely used materials in this technology are plastics.

- Stereolithography (SLA)

It is a technique whereby the UV light will selectively use some parts of a liquid photopolymer reservoir. It will later fill layer by layer until it solidifies to a 3D object. The products will have excellent surface quality in the end.

Unfortunately, most of these objects will break easily. You will also compromise their quality if you expose them to light. You can use this technology on non-functional prototypes and artistic projects.

- Selective Laser Sintering (SLS)

Many users take advantage of this technology to create plastic parts. A laser will fuse some plastic powder particles layer upon layer. As you complete, you will have to give it time to cool. After that, extract bits from the powder as you remove the remaining particles.

You can use this technology to work with various materials. The most used plastic, in this case, is nylon. You can also use glass-filled nylon for more robust products. Also, one can use PEBA, which is a flexible plastic.

- Multi Jet Fusion

It is a recent technology from HP Company. You will use a batch of powder to print plastic powder. The process is faster since the powder will require less heat to complete the process. The method will consume less time to heat and cool.

The downside of this method is that you have a limited choice of materials. You will also have to 3D print parts in black nylon and grey only.

- PolyJet

The process involves creating high-quality resin objects having a smooth surface. The principle is similar to that of a 2D inkjet printer. You can create parts in several colors with translucent parts.

- Clip

The acronym standard for Continuous Liquid Interface Production. It uses a high-speed to create numerous top-quality resin parts. You can create complex parts within 10 minutes. The process uses a continuous sequence that involves UV images. You project them in a liquid resin bath.

It will later solidify. The unique part of this process is that it will not involve layer by layer design. The object build is only a continuous process. Also, the process has numerous applications. For example, Adidas uses this method to manufacture the soles.

- Selective Laser Melting (SLM)

It is a unique 3D process that involves fusing the metallic powder, layer upon layer, to facilitate melting. The process requires much heating as well as a long cooling process for better results. The good news is that all the items that result from this process are particularly sturdy and durable.

- ColorJet

You can use Colorjet Technology to create multicolor printed 3D printed parts from fine mineral powder. The printer will apply the paint during the manufacturing process. The technology happens to be the fastest in producing a colored object.

Due to the fragility of the products, you can use this technology for decorative purposes only. You can use this technology on apps to scan 3D objects and people.

- Binder Jetting

It is a 3D printing technology from ExOne. It is one of the cheapest methods as it uses unique processes to infuse metal powder. You will use a binding agent, deposited in powder before heating and fusing.

Such a design will eliminate any need for high-temperatures to enable an efficient process. One advantage of this method is that heating and cooling are relatively shorter.

- Casting

Casting is a method that is useful in the creation of pieces of jewelry. The technique begins by creating the initial version in wax. After that, you create a plaster mold. The final process involves injecting the liquid metal inside. It will mold it properly for the final product.

- Direct Metal Laser Sintering (DMLS)

It is a popular method that involves partially melting the powder. The process will require less heating and, consequently, less cooling times.

3D Printing in Fashion

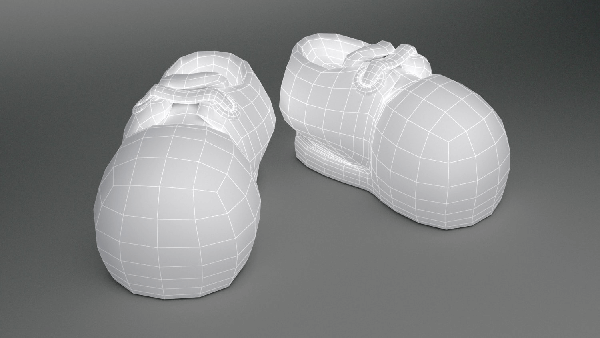

1. Shoes

3D printing is becoming more practical in the shoe industry. Most of the many innovative designs are due to 3D technology. Additive manufacturing is responsible for creating high-performance shoes.

Adidas has been using this technology to make various soles. You can still use this technology to customize accessories and clothes painlessly. There is a demand in better designs; hence this method will increase your earnings.

2. 3D Printed Glasses

You can use 3D models to make innovative frames. You can still make a custom-made glass for a particular client. The 3D frames are typically lighter hence will offer an improved comfort to the user.

3. 3D Printed Jewelry

You can use 3D technology to make refined jewelry. You can create jewelry from precious minerals like silver, gold, and brass.

Benefits of Additive Manufacturing

Additive manufacturing involves creating intricate designs that will be impossible while using traditional methods. Since the process is digital, it has a few steps that you may involve to get the desired design.

Below are some of the advantages that you will encounter while using 3D technology.

1. Time-Saving

The whole process is time-saving. You may not need special machinery or intermediaries to produce your desired product. One will only access the CAD files on the computer and get the process on.

You will also make some changes while the process is ongoing. It saves time as compared to traditional methods, which will require several approvals before you affect any change.

2. Save material

3D technology is a process of creating an object by adding layer upon layer. You will not use the entire material and later get rid of the unwanted part. As a result, traditional methods are full of wastage.

4. HealthCare

The healthcare industry is one of the primary beneficiaries of the 3D technology. Doctors use it to enhance their efficiency and precision in their work as they serve patients. The scientists are making custom dental implants to service their patients.

Interestingly, the 3D drug is now available to treat epilepsy patients.

5. Defense

Some developed countries want to use this technology to advance their weapons. For instance, the US navy will be using 3D technology to convert its navy ships into floating factories.

They will be in a position to manufacture some supplies and parts on board.

4. Added complexity

The process of additive manufacturing allows designers to construct complex structures than before. The method will enable one to make an object that could take longer to manufacture. Some of those processes require welding of some pieces or require assembly. You can make them within a shot by using 3D technology.

5. Education

3D is a learning tool in the classroom. Some students that take science subjects like chemistry, physics, and engineering will be developing real-life objects using 3D technology. Teachers will be using a 3D printed map to teach geography.

Moreover, as biology students, one can use the 3D printed body parts to learn the subject. Overall, one can use 3D technology to enhance learning and creativity at various institutions.

Final wrap

Technology is among the significant aspects that are civilizing society. Each version comes with better features to increase efficiency and profit. It will help if you considered the changes for you to stay relevant in your endeavors.

Most importantly, 3D technology is proving to be more effective than other traditional methods. It saves the material and the time used to create a similar design by using conventional methods.

You must adjust to the new changes for you to encounter more gains. Indeed, 3D technology is transforming how people manufacture complex objects within a short duration. You will save a lot of material since the process does not encourage wastes.

Decide now, and you will never regret it again.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.