Candy is one of the most popular confectioneries. Whether you are in this business or you are pursuing as a hobby, you should be aware of the candy molds. These molds are the ones that you will use to create different shapes and designs of candies.

In this article, we are going to unravel everything that you should know about chocolate candy molds.

Contents

Types of Candy Molds

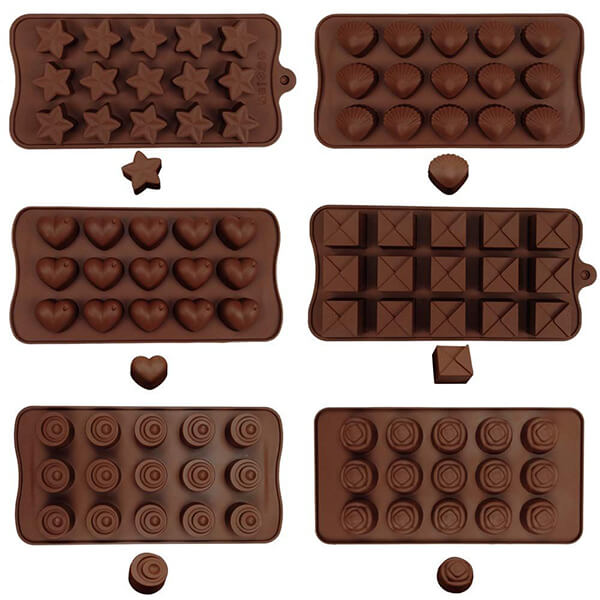

By now you must be aware that not all the candy molds are the same. They have different properties. This is mainly because there are different types of candy molds.

Flat candy molds

When it involves candy molds, there are three basic categories to settle on. You’ll take the straightforward route and make lollipops using flat molds!

They are the most popular choice of most lollipop candy makers. Believe it! You’ll easily make amazing shapes – berries, fruits, hearts then on. The first place to seem is on-line.

Make an inquiry to seek out lollipop molds that appeal to you. Local craft stores also are great places to seem, though. Consider buying casual cooking supply shops also.

Resin candy molds

Another type of candy molds is plastic, resin, or rubber molds. These are all flat. Pour some hot candy within the mold. Let it harden slowly.

Flat molds lately feature different types of styles, which permit you to simply press candies. It is so simple to form several candies at a time.

Once your candy cools down, gently flip your mold, so it pops out easily. Put some force on its backside to permit the mold to flip gently.

Once you are done, you’ll see an imprinted design onto aside and a flat and plain look on the opposite side.

3-D Candy Molds

3-D molds happen to be quite adorable too. And this sort of mold is right for lollipops. Using these molds gets you greater shapes as against the flat molds. Instead of being entirely flat on one side, most of the fashionable 3-D molds produce candies larger thorough and shape on all sides.

Very much like those flat molds, 3-D molds are simple to manage and handle. Most of today’s 3-D molds accompany two pieces. While a bit remains at the mold’s face end, the opposite one is at the mold’s back part. Just pour a touch candy into the side. Make certain that it’s almost reached the highest. This allows the candy to harden.

You furthermore may have to pour a touch candy into the rear side of the mold. It is best if it’s 0.25-inch down from the highest level. Allow your candy to harden. If candies at the rear become nearly hard, take it off the mold’s front side.

Put it on the rear end. When your candy hardens slowly, both of those sides remain together. And you’ll find many molds. Find molds that come as single-piece items and have halves at two sides.

These molds can easily fold together. Pour the candy into each side together. Fold the molds to half to urge both halves done before they get hard.

Hollow candy mold

Another category is hollow molds. They’re actually not for lollipops. They’re used for filling up the middle of candies with nice treats like honey, cream, or spread. These are best with typical hard candies.

You will also make use of them for your chocolates, too. When chocolate melted, you ought to apply some chocolate on each side of the mold employing a small brush. You will use the refrigerator for cooling down the chocolate faster.

The entire process is meant to be done multiple times until you’ve got chocolate on the edges of the molds. When the chocolate layer is thick enough (you cannot see through), just insert the filling into the mold. Cover it using the residual parts of the chocolate.

Materials for Candy Molds

Which materials are the best for candy molds? Due to the delicate nature of candy molding, finding the right material for this process can be a little bit challenging.

Here are some of the most common materials for candy molds.

Clear Plastic: The majority of our molds are made from FDA approved clear plastic. They can be used for a variety of food uses, particularly chocolate. The can not be heated to high temperatures, so they should never be used in the oven or with hard candy. They will melt.

Clear plastic molds can also be used for a variety of crafts, including soap making, bath bombs, concrete, plaster. So versatile! Just don’t mix your chocolate and concrete.

White Plastic: These molds are similar to the clear plastic molds, but they can reach temperatures above 350* F. Therefore, they can be used in the oven or with hard candy. Additional crafting uses include wax from candles or crayons.

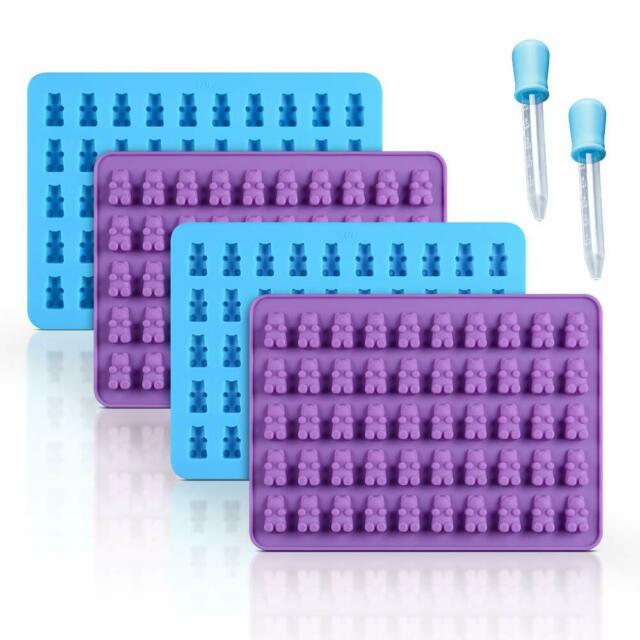

Silicone: These molds are very versatile and extremely easy to use. They can be used for candy making and baking with ease. They are flexible and durable. Specific applications may have more issues with the release (chocolate if it is not tempered, wax if it is not cool), but the flexible qualities are beneficial for other uses (bath bombs work great with silicone molds).

Polycarbonate: These molds are made from durable polycarbonate. The rigidity of these molds brings out the finest detail and design to your chocolates or hard candy. Clear plastic allows you to see when the chocolate has set and pulled away from the mold. These molds are used by professionals for professional results.

Using polycarbonate molds is a great way to improve your chocolate and candy making.

Aluminum: These molds serve one purpose – hard candy suckers! They are durable and produce great results! They are a worthy investment is hard candy is a craft you enjoy.

The good thing about aluminum materials for candy molding is they are extra strong.

How to Use Candy Molds-Step by Step Guide

Step 1: Wash molds before using to get rid of any dust from manufacturing, warehousing, and shipping materials.

Step 2: For best results, the mold must be level. Approximately most of our molds will sit level on their own. However, molds that have odd size cavities will have to be supported during a level position.

There are two methods of leveling candy molds. One method is to position the mold atop a suitably sized bowl. Another approach is to fold a towel during a shape that will hold the mold level. Placing a bit of paper atop the towel will protect it from drips.

Step 3: Fill the candy mold: The mold cavities are filled by one among the subsequent or a mixture of the following:

-Pouring from the melting container – best for giant mold cavities.

Spooning the chocolate into the mold – best for little to medium size mold cavities.

-A squeeze bottle – best for small and tiny mold cavities because it provides the simplest control. The chocolate could also be kept soft by placing the bottle in warm water or heating during a microwave.

-A shed resistant brush – requires patience and a gentle hand and is beneficial just for filling tiny mold cavities or painting the mold.

Step 3: Release trapped air bubbles by rapping the mold sharply against the countertop several times immediately after pouring.

Step 4: Demolding – it should never be necessary to force the chocolate from the mold. I usually like better to air cool molds until the surface is tough to form, handling them efficiently. The molds are then placed during a freezer until they de-mold easily – typically 5 to eight minutes counting on the dimensions of the mold and your fridge.

Do you spray candy molds?

No got to spray or coat chocolate molds with any type of oil. As long as you used the right molding chocolate and let it completely set within the refrigerator, your candy will easily release on its own.

How long does it deem the candy to line up in molds?

How long it takes for the candy to form within the molds completely depends on the dimensions of the plastic candy mold. Smaller molds might take 5 to 10 minutes, and medium to large molds could take anywhere from 15 to twenty minutes.

How to Take Care of Candy Molds

As we have seen, candy molds are somehow different from other types of molds. You need to be extra careful with the way that you handle them.

If handled properly, candy molds will serve their purpose in the way that you want. Here are some of the best ways of using candy molds:

-Do not pour hot chocolate or candy into the mold. Chocolates whose temperature is above 160 degrees F can cause physical and structural damage to the candy mold. So ensure that your chocolate is below 90 degrees F.

-You should never put candy molds in a dishwasher

-Wash the candy molds before using them. This is vital because candy molds are required to meet the highest levels of hygiene.

Chocolate Candy Molds Manufacturers in China

Would you like to stretch the horizons of your candy molds? Consider having the molds from the most creative candy molds manufacturers. This is definitely what defines us at Roche Industry.

Related source links:

Handbook: Everything You Should Know About Dice Molds

Handbook: The Ultimate Guide to Silicone Molds

Handbook: The Ultimate Guide to Resin Molds

Everything You Should Know About Candle Molds

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.