Contents

What is Rapid Manufacturing? Definition

Rapid manufacturing can be defined in different ways. We can define it as a set of development processes that are designed not to reduce the development time while at the same time, reduce product development time.

Another way of defining rapid manufacturing is the use of 3D software, which is connected to an assortment of equipment to accelerate the manufacturing process. This explains the name ‘Rapid’ as the whole process is faster than the normal manufacturing.

Alternatively, rapid prototyping can be viewed as techniques of manufacturing solid objects by sequentially delivering the requirements from one step to another. This method is done with the goal of utilizing speed while minimizing the cost of manufacturing.

Brief History of Rapid Manufacturing

Rapid manufacturing is a relatively new technology in the world of manufacturing. It is derived from the 3D printing and Rapid Prototyping processes.

During the early days, 3D printers were introduced to shorten the production time of products. They ensure that the time-frame between the design and the prototyping is way much shorter.

3D printing and rapid manufacturing techniques were tested during the 1980s. The first patent for rapid manufacturing was applied in 1980. Although it faced some level of resistance, it was until 1986 when this method of manufacturing became commercial.

Rapid manufacturing has improved by a big margin in recent years. It is now being used for making complex products and components. It is also applicable in a wide range of industries.

How Does Rapid Manufacturing Work?

While learning the basics of rapid manufacturing, it is vital to have a clue about how it works.

Like any other type of 3D printing, rapid manufacturing entails a combination of the CAD system with a machine. The two work together to achieve the desired goal.

First, a 3D CAD design of the product is created by computer software. Different software or programs are used for creating the design and the most common ones include Autocad and ProEngineer. There are many alternative programs out there that can do the job.

The 3D design is then sliced into layers of different thickness according to your specifications. The profiles are then stored in a particular format, which in most cases, is STL machine data.

Another computer program will convert the STL data into machine data. This information is then channeled to the operating machine where fabrication and other metal treatment methods are executed.

This process repeated several times for creating each layer of the machine or product.

The last step of the rapid manufacturing entails removing the part of the machine that has been processed. Leaning and polishing may be done to improve the outlook of the machine part.

Here are some key actions that take place during the rapid manufacturing process:

Molding the material from liquid to solid form: Through a casting process, the material is transformed from the liquid form to the solid form. The liquid is poured into a die and as it cools, it will take the shape of the preformed mold.

The newly formed object will then removed from the mold.

Rolling, stamping, and forging: External forces and operational techniques are applied to the material. These activities are designed to change the design, shape, and even the dimensions of the product.

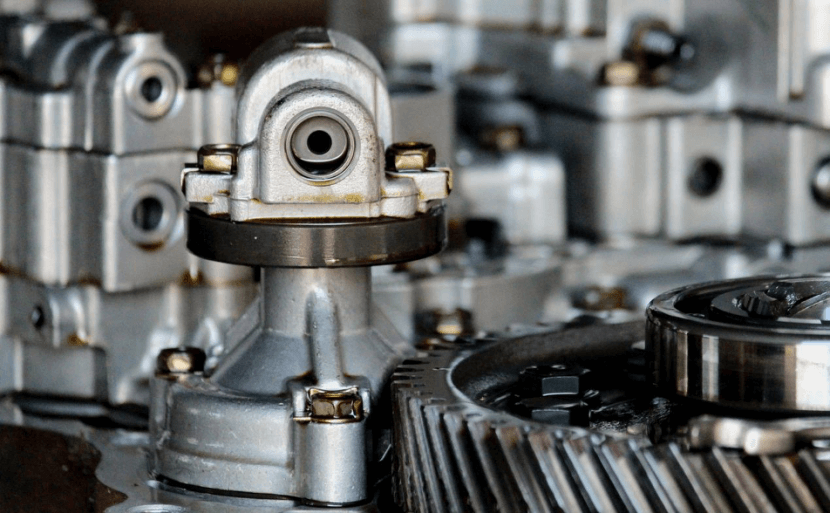

Metal Machining: The material is cut so as to conform to the desired specifications of the product. Different metal cutting tools such as grinders and lathe mill are used for doing this task. The cutting process is accurate as it is controlled by the computer.

Joining the parts: Molding and forming techniques are deployed to weld the parts that have been processed. There are also programs that are used for controlling this task.

Types of Rapid Manufacturing

Rapid manufacturing is not a single process. There are seven different categories of this type of manufacturing the difference is to take care of different needs of products.

These are the seven types of rapid manufacturing:

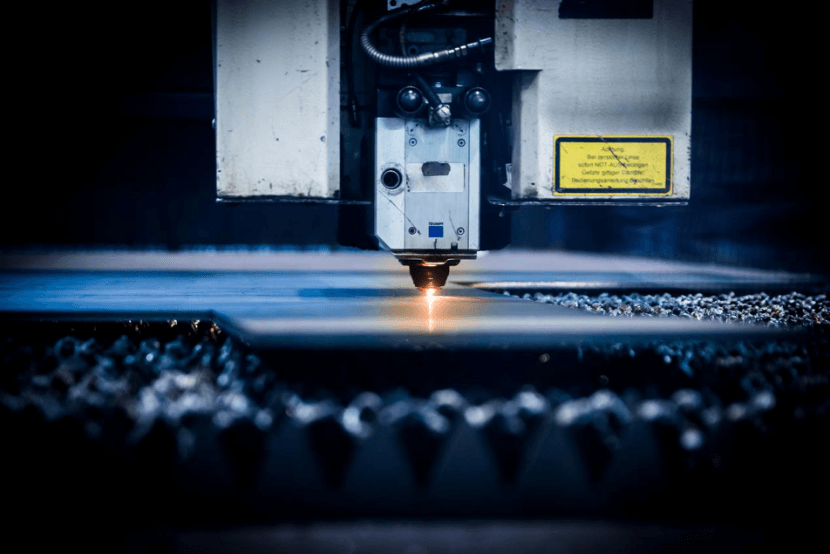

1. Powder Bed Fusion

There are various processes that are encompassed under the powder bed fusion manufacturing technique. These are Direct metal laser sintering (DMLS), Selective laser melting(SLM), Selective laser sintering(SLS), and Electron beam melting(EBM)

Powder Bed Fusion techniques use either electron beam or laser beam to cut and change the structure of a material. All the PBF metal machining processes involve spreading powder over the previous layers. | A roller a blade is used for spreading the powder.

There are several reasons why powder bed fusion is a preferred method of rapid manufacturing. One of them is it is suitable for different types of prototypes. The method is also cheaper than most rapid manufacturing techniques.

2. Material jetting

This method of rapid manufacturing can be compared to creating an object or product using the two-dimensional technique.

The hot metal material is jetted onto a platform or a build surface. It will then solidify to form a product that has several layers. Ultraviolet rays will then be used to harden these layers.

One chief advantage of this method is the high level of accuracy that it shows. It is also possible to allow multiple layers of material on the object. This method is mainly used in the manufacturing of plastics and polymers.

3. VAT Photopolymerisation

This is a form of the rapid manufacturing process in which a VAT of liquid resin is used for constructing a model. This type of model still featured different layers and the ultraviolet lights perform the primary role of hardening the resin.

This method is different from the powder methods as it does not feature structural support during the building phases. The resins are solidified through either photopolymerization or by the UV rays

One of its key advantages is it has high levels of accuracy. It is also a time-saving method. The method is ideal for the manufacture of resins and polymers.

4. Sheet lamination

In the context of rapid manufacturing, sheet lamination is used to refer to either the laminated object processing method or ultrasonic rapid manufacturing. Both the two methods use sheets and ribbons.

For the ultrasonic manufacturing, ribbons or sheets of metals are fused through an intrinsic welding process. For the laminated object manufacturing, layers of metals are joined together using an adhesive material.

Like other methods of rapid manufacturing, sheet lamination entails working on each layer sequentially. This means that each layer is processed before moving to the next layer.

Sheet lamination can be used for the processing of both metals and plastics. It is also used in paper manufacturing.

5. Material extrusion

This is considered as the most affordable method of rapid manufacturing. It is commonly used for the basic builds whereby the material is drawn through the nozzle, heated then deposited in layers.

The nozzle is designed to move horizontally while the platform moves up and down to receive the material. The pressure at which the material exits the nozzle should be kept steady to maintain the uniformity of the layers.

This method is used for different materials, including plastics, ABS, and even for some metals.

6. Directed Energy Deposition

This method is commonly known as laser-engineering shaping, while other people call it 3D laser cladding. This method is used in case you want to add new material to an already existing product or object.

In this process, the nozzle for the material is allowed to move freely along all the axes. The material can either be in the powder form or molten form.

As a method of rapid manufacturing, material extrusion cannot be used for plastics, polymers, and ceramics. It is suitable for only some metals such as titanium.

7. Binder Jetting

This is just another word for 3D printing. Binder jetting is a popular method of rapid manufacturing due to several reasons. It is versatile, robust, and highly effective.

This method uses both liquid and powder forms. The binder, which is in liquid form, will act as an adhesive, bringing together the layers of powder. A print head is designed to move along all the axes of the design.

Since it is a versatile manufacturing method, binder jetting is used for manufacturing different types of materials. They include metals, glass, ceramics, plastics, polymers, among others.

What Materials Can Be Processed through Rapid Manufacturing?

Let’s say you are contemplating using the rapid manufacturing method for your products. What types of materials apply to the process?

Here is a list of the materials or medium that you can process using a rapid manufacturing method.

Metals: You can have a wide range of metals that can be processed by the rapid manufacturing method. The most common metals include steel cobalt, Chrome, Aluminum, Titanium, among others.

The metals processed through this manufacturing method can be used for their respective areas of application.

Ceramics such as silica gel, porcelain, and carbide

Polymers such as ABS, polycarbonate (PC), Epoxy resin, polyamide, among others.

If you are not sure whether the metal or plastic is compatible for rapid manufacturing method, consider asking the rapid manufacturing experts. They will help you to assess the viability of this method on your material.

Advantages of Rapid Manufacturing

As a manufacturer, should you consider using rapid manufacturing for your products?

For years, rapid manufacturing has proven to be a viable manufacturing method. Here are some of the benefits that manufacturers can gain from using it:

1. Reduces the development time

Manufacturers are choosing a rapid manufacturing method because it saves on time. Just as the name suggests, this manufacturing method is geared towards mass production within a limited time.

Instead of waiting for months to complete your projects, you will be getting your processed parts and components within a few days.

You will also save time since the production of parts will be done by other entities. This means that the activities at your work station will go on without any interruptions.

2. Reduces the production cost

There is no doubt that rapid manufacturing is a cost-effective method of manufacturing different parts and components. You will be able to get your parts done without incurring a high cost.

This can be achieved in many different ways. For instance, you will not have to buy rapid manufacturing equipment and tools. The rapid manufacturing service company already has the equipment for the job.

The ability to manufacture large volumes of products within a short time helps to lower the cost of production.

3. Quality products and parts

Despite maximizing speed, rapid manufacturing has a high level of accuracy. The layers of the material are aligned with each other accurately. This means that the product of the process is likely to have minimum flaws.

4. Easy to introduce changes

Rapid manufacturing is very flexible. It provides an allowance for changing the specifications of the product without having any adverse effects on the whole production process.

Implementing relevant changes in most manufacturing methods can be a difficult task to achieve. You may have to spend more just to introduce a small change.

5. Minimum wastage of resource

As we have seen, various methods of rapid manufacturing are quite efficient when it comes to utilizing the materials. They ensure that no material goes to waste during the whole process.

Also, the method does not waste other resources that are used during the production process.

Roche Industry: Reliable Rapid manufacturing Services

Would you like to improve the quality of your products? Or, your if your market share has expanded, it is time to switch to the rapid manufacturing method.

At Roche Industry, we offer accurate, rapid manufacturing services. We have all the requirements to deliver quality parts and components. This is due to our high-tech machines and qualified workforce.

To get this service, simply contact us, and we will be ready to handle your rapid manufacturing project.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.