The properties of steel can be improved in a way that suits a specific application, and that goes beyond the chemical compositions. Besides, the manufacturing process can be used to impact the use of steel, even if the specs and grade are the same for the said product. One such area of distinction in pre-fabricated steel is determining the differences between hot rolled steel and cold rolled steel. What are the Differences between Hot rolled vs cold rolled steel?

Contents

What are the differences between hot rolled and cold rolled steel?

As the name sounds, the primary difference between hot rolled and cold rolled steel lies in the rolling process. The hot rolling process is done with heat while the cold rolling process is done at room temperature. These methods have an impact on the overall performance of individual steel. However, it is essential not to mistake them for other specifications and grades of steel. The grades and specs of steel are affected by the chemical compositions and relate directly to the performance rating of steel. In that way, different grades of steel can either be hot rolled or cold rolled, and this includes the alloys of steel also.

As much as it may seem apparent, it is essential to note that every type of steel is best suited for specific applications and not others. Knowing the right kind of steel to use for a project can save you unnecessary spending on raw materials. Besides, it will save you time and money on other processes. One way of doing things right is understanding the differences between hot rolled, and cold rolled steel.

Hot rolled steel

Hot rolled steel is a type of steel product that has been processed by passing it through exceedingly high temperatures of more than 17000F. This temperature is way above the average recrystallization temperature for most steels. This process makes it easier to form steel, and the end product becomes more natural to work within different projects.

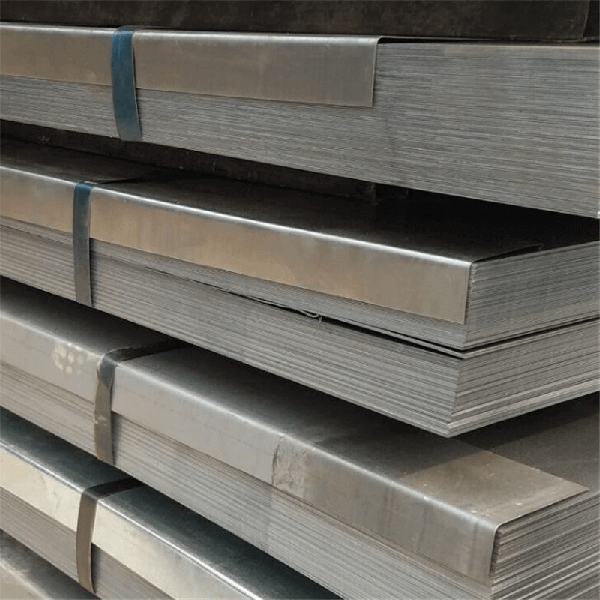

To make hot rolled steel, manufacturers start with billets, which are large and rectangular. The billet is passed through a heat chamber and then goes through pre-processing where it is flattened into large rolls. After that, it is kept at high temperatures as it runs through series or rollers that give it the required finishing for shape and dimensions. The steel is pushed through rollers at a very high speed while still hot. Rolled steel is spun into coils and left for some time to cool to make sheet metal. For other shapes and forms, steel is sectioned and packed.

Steel shrinks slightly on cooling, and since hot rolled steel is left to cool after processing, there is always less control over the final shape. This drawback makes it not suitable for projects that require precision.

Hot rolled steel is often suitable for applications that do not require minutely specific dimensions and shapes. For instance, the most appropriate uses for hot rolled steel are railroad tracks and construction works.

Features of hot rolled steel

It is often easier to identify hot rolled steel by the following specs.

Scaled surface: The surface of hot rolled steel show some remnants, which is the result of cooling from extreme temperatures.

Rounded edges and corners: steel shrinks in the process of cooling, leaving less precise finishing around the edges.

Slight distortions: cooling may force the creation of slightly trapezoidal shapes instead of perfectly squared angles.

Benefits of hot rolled steel

Hot rolled steel is cheaper compared to cold rolled steel because it requires less processing. Additionally, hot rolled steel is often free of internal stress that arises from hardening processes.

Hot rolled steel is preferable in projects that require overall material strength as opposed to dimensional tolerance and surface finishing. However, descaling can be done on hot rolled steel by grinding, sandblasting, and acid-bath pickling to make it usable for projects that require surface finishing. Descaled steel also makes surface painting and coating much easier.

Cold-rolled steel

Cold rolled steel is mainly hot rolled steel that has gone through additional processing. After cooling hot rolled steel, it is then re-rolled at room temperature to give it better surface finishing and precise dimensions.

Cold rolled steel can be used to describe a wide range of finishing processes that steel is put through. However, the cold-rolled technique applies to steel that undergoes compression between rollers. Other forms that are pulled like tubes and bars are referred to as “drawn” not “rolled.” Some processes used for cold finishing include turning, polishing, and grinding. Each of these processes is used to transform hot rolled steel into a more refined form.

Features of cold-rolled steel

The following specs can often identify cold-rolled steel.

- More refined surface finishing

- Oily and smooth surfaces

- Well defined edges and corners in bar forms

- Better concentric uniformity and straightness in tube forms

Benefits of cold-rolled steel

Cold rolled steel is preferred in projects that require more refined surface quality and precision as compared to hot rolled steel. However, cold-rolled steel undergoes various finishing processes to achieve such fine-tuning, and that makes it more expensive compared to hot rolled steel.

Cold rolled steel is harder and more heavy-duty than hot rolled steel. The strength and resistance against tension are brought about by work hardening and shaping at lower temperatures. This makes it more resistant to impact and hard to deform.

These additional processes and treatments also bring internal stress within the steel and can cause warping.

The bottom line

Every material has its pros and cons. Besides, the choice for the right material for a project depends on what you are looking to build. Steel materials offer the building block for most construction and structural projects. Whether hot rolled or cold rolled, you have to know the specs that best suit your building requirements.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.