Contents

PLA vs ABS Overview

PLA and ABS are the two most normal FDM (Fused Deposition Modeling) desktop printing materials. Both are thermoplastics, which means they enter a delicate and moldable state when warmed and afterwards come back to a strong when cooled. By means of the FDM procedure, both are liquefied and afterwards expelled through a spout to develop the layers that make the last part.

This article will examine the principle contrasts between these two normally utilized materials. Read on to understand everything about PLA vs ABS.

Background information on PLA and ABS

It is clear that the world has moved to the 3D printing method of manufacturing. Most solid products in the market are as a result of the 3D printing process. It is disruptive and game-changing technology.

3D printing offers a similar guarantee of power over the physical world yet in an increasingly technical manner.

3D printing has been around throughout recent decades is as yet giving customary individuals useful assets for product design and development.

This is an additive fabrication process that can transform digital computer geometry into physical products utilizing an assortment of materials.

From those old fashioned desktop printers to the eventual fate of added substance fabricating, 3D printing has progressed significantly since the late 80s.

There are many different factors that define the success of the 3D technology. Maybe the most significant piece of a 3D printing process is to utilize the correct material.

Furthermore, with regards to materials, PLA and ABS are the two most basic kinds of materials utilized for 3D printing, predominantly FDM 3D printing, with each being exceptionally unique.

But, what are they and how are they related to 3D printing?

What is PLA- Definition

Poly Lactic Acid, or regularly alluded to just as PLA, is an ordinarily utilized corn-based thermoplastic that is utilized by each FDM 3D printer available.

It is one of the most widely recognized kinds of 3D printing fibre and simple material to work with.

It is a water-dissolvable thermoplastic which can be utilized for help material and can be flushed off with water and reused.

As it is fabricated from cornstarch, the lactic corrosive is polymerized during the procedure.

What’s more, the best part, it very well may be reused and in light of the fact that it is non-petrochemical plastic, it’s an environment-friendly of material.

What is ABS Filament?

Acrylonitrile Butadiene Styrene, or ABS, is a typical thermoplastic polymer that is mainly utilized for injection molding.

It is an oil-based plastic that is solid and tough, yet it’s not as much eco-friendly as PLA in view of its oil-based plastic arrangement.

It ABS has a higher melting point and longer life expectancy than PLA, in addition to it, has the upside of a lot higher glass change temperature.

ABS is the favoured selection of materials for parts and products that are probably going to be exposed to temperatures up to 100 degrees celsius to guarantee that the printed objects hold fast to the platform.

PLA Printing Process

PLA is somewhat simpler to print with than ABS because of its lower print temperature and its capacity to print on and stick onto an unheated print build platform.

In spite of not requiring a heated print bed, numerous PLA users despite everything print at a print bed temperature ranging between 50 to 60 degrees Celsius.

They additionally use “blue painters tape” applied to the outside of the print bed.

Furthermore, PLA filament can print at higher speeds; anyway, that relies upon the printer utilized and what the print work is.

ABS Printing Process

Because of its higher liquefying point, ABS must be printed at a higher temperature of around 190 to 200 degrees Celsius or more.

It additionally should be imprinted onto a heated build platform. Printing on an unheated surface will make ABS plastic twist and warp, which could either prompt the print falling off the print bed or unacceptable print quality.

Print bed temperatures for ABS plastic, for the most part, run from 90 to 100 degrees Celsius or sometimes more than 100 degrees.

Guaranteeing the print bed is smooth is additionally significant and different solutions are now and then applied in advance to the print surface.

These solutions could incorporate a blend of ABS and Acetone or hairspray.

Difference Points of PLA vs ABS

Here are numerous parameters that we can use to differentiate ABS vs PLA.

PLA vs ABS: The Basics

PLA is one of the most widely recognized thermoplastic materials utilized in 3D printing, and it is a corn-based biodegradable thermoplastic polymer made from sugar plants, for example, sugarcane, corn, and custard.

It tends to be reused, and in light of the fact that it is non-petrochemical plastic, it’s an eco-friendly type of material.

ABS, on the other hand, this is anis an oil-based thermoplastic with a lot higher glass change temperature however isn’t ecological cordial as PLA due to its oil-based plastic arrangement.

In contrast to PLA, it very well may be hard to work with also and requires a heated form stage for printing.

Melting point: PLA vs ABS

The two PLA and ABS filaments are the most widely recognized materials utilized for 3D printing.

Notwithstanding, PLA is more diligently and adaptable than ABS, however, includes a far lower melting point than ABS, which is around 180 to 220 degrees celsius.

ABS, then again, is viewed as undefined, which implies it has no fixed melting point.

ABS is made of styrene and acrylonitrile within sight of polybutadiene which permits the polymer to relax step by step as temperature rises.

PLA shows higher friction than ABS making it incredibly hard to expel.

Performance: PLA vs ABS

PLA filaments have more prominent rigidity however are moderately very comparable in performance as the ABS filaments.

PLA has progressively reliable quality when yielded from the extruder, and it does no radiate a bad smell.

Also, it infrequently bubbles or wraps during the printing stage, making it perfect for increasingly nitty-gritty items.

ABS, on the other hand, are not prescribed for exceptionally definite structures since it is inclined to rising during the extrusion stage of manufacturing.

In contrast to PLA, ABS can likewise be hard to work with, and it requires a heated build platform, which numerous at-home printers don’t have.

PLA VS ABS: Application Areas

Both are the favoured selection of materials for FDM printing and are regularly comparative in cost. Yet, ABS is most appropriate for applications where strength, thermal stability, and malleability are required.

It is used in an assortment of ways from modern applications for extrusion to youngsters’ toys; for example, Lego blocks to instruments.

PLA, then again, is simpler and more secure to use and is additionally significantly more fragile than different thermoplastics.

PLA plastic is frequently utilized for food containers and plastic movies for packaging. It is less durable than ABS, which improves its aesthetic value uses as opposed to mechanical uses.

Contact with food

PLA is FDA endorsed for food use. It is consistently utilized for the processing of food-related products. Be that as it may, it is prescribed that the filament manufacturer affirms that it is protected to do as such.

It ought to be noticed that the crude material, PLA tar, is treated in the filament producing plant and added substances are included which alter its properties and colouring.

The material is then stored and handled in coils, passes through the extruder and fuser of our printers, is saved on the bed full of enamel also the unpleasantness and interior holes of FDM printed parts.

Thus, regardless of whether the first pitch was endorsed for nourishment use. It can never be guaranteed that the parts produced with PLA are quickly appropriate for food use. This is because each PLA has some unique components.

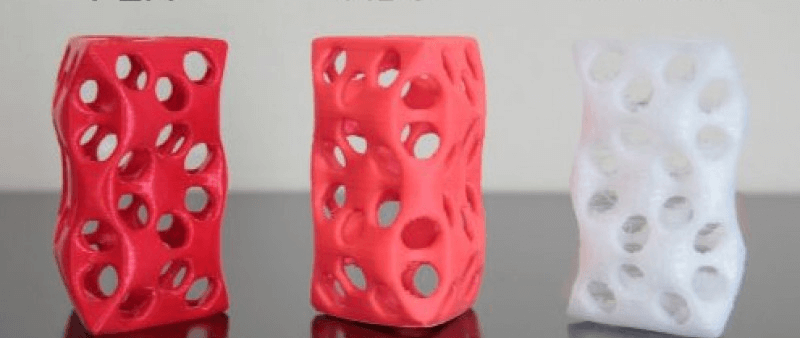

Which one is Accurate? PLA vs ABS Printing

Although both the PLA and ABS are accurate, it will be imperative to distinguish the level of accuracy between these two. Which one is more accurate?

ABS’s greatest disservice with regards to print quality is its inclination to twist and coil at the base, or even at times in the centre of the print.

ABS additionally experiences more difficulty with regards to getting finer details like sharp corners, which will frequently be printed with a slightly adjusted edge.

To improve ABS prints, numerous individuals utilize a technique for washing their prints in an Acetone shower or Acetone fume. This current smooth’s out the print lines and gives a polished, glossy appearance.

Contrasted with ABS, PLA displays considerably less print twisting and warping.

Since it experiences to a greater degree a stage change than ABS, it can likewise print finer details of the material.

Dynamic cooling empowers PLA to print a lot sharper corners without the danger of twisting, distorting and breaking.

PLA can likewise be printer at a higher stream rate, which prompts more grounded and stronger layer bonds. ABS components are as yet more stable and structurally stronger because of the plastic’s mechanical properties.

Which 3D Printing Produces Fumes: ABS vs PLA

If you have been around 3D printers, particularly those printing with ABS know there’s an unmistakable plastic smell that can be hostile to the nose.

3D printing fumes can be a tremendous potential mood killer for those needing to buy a 3D printer, and many are considering how risky the plastic particles really are.

Guaranteeing your printer is in a very much ventilated zone and the filament utilized is liberated from any contaminants will lessen the smell significantly.

Printing at the right temperature will likewise decrease the measure of fumes discharged into the general condition.

So, between ABS and PLA, which one produces toxic fumes?

ABS is made of three main plastic components which are Styrene, Butadiene and Acrylonitrile.

All these plastic components release toxic fumes when heated. So, they will be harmful to anyone who inhales the fumes containing these compounds.

On the other hand, PLA is made from natural materials which are biodegradable. One such material is corn. When burnt, the materials for PLA don’t emit toxic fumes.

Instead, PLA will release a smell that can be compared to the cooked corn oil. However, you need to be extra careful as PLA can also release ultrafine particles into the environment. These particles are known for having a dangerous impact on human beings and the environment in general.

So, in terms of fumes, both PLA and ABS release some fumes only that the ABS filament is considered to be more dangerous.

Storage PLA vs ABS

Both ABS and PLA filaments absorb moisture from the air on the off chance that they are not stored away appropriately.

Anyway, your filament won’t be destroyed in two or three days, and moisture can be expelled by drying it with any semblance of a nourishment dehydrator or stove.

Forestalling moisture absorption can be accomplished by putting your filament in an air-tight compartment or pack.

Constant accumulation of moisture on the ABS material can diminish its print quality and even structural integrity.

The same applies to the PLA filament, whereby it can be discoloured, and its bonds are broken down.

It is important to store both the ABS and PLA under dry conditions.

Conclusion

In conclusion, although the two PLA and ABS filaments are the most well-known thermoplastic materials utilized for FDM 3D printing, each has its unique properties that make themselves to either progressive nitty-gritty structures or increasingly sturdy parts.

PLA is simpler and more secure to utilize and is likewise substantially more weak than different thermoplastics, yet ABS is most appropriate for applications where quality, thermal dependability, and malleability are required.

Whether you want ABS or PLA services, let the professionals do it for you. We at Roche Industry provide both the ABS and PLA 3D services in China. We help manufacturers to achieve their dreams.

Related source links:

Handbook: Everything you need to know about PETG

PETG vs PLA: What are the Differences?

Polycarbonate vs Acrylic: What are the Differences?

Nylon vs Polyester: What are the Differences?

Trivex vs polycarbonate: What are the Differences?

White paper: The Complete Guide To thermoforming

Everything You Need to Know about PVC Pipe Sizes

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.