One of the most challenging stages is testing the designs and assumptions is prototyping. During prototyping, users will be trying out new products as they present the feedback to the team for possible consideration of future outcomes.

The team will be experimenting with different ideas while capturing errors before mass-producing the concept. If the prototype gets closer to the final product, the team will have more confidence to launch it.

Several methods can create prototypes. The purpose of allowing it to undergo several stages is for it to make it succeed it the market. Let’s dig a little deeper.

Contents

What is prototyping?

It is a process involved as the new product develops. The team will present it in real life on how the product will behave. The role of a prototype is to test a particular system. Interestingly, Computer-Aided Design (CAD) can also produce computer simulations.

You can also test the feedback that comes from computer simulations and investigate any deviations. At the end of testing, one will determine if the product if ripe for the market or not.

Importance of Prototypes

- It simulates the real product

The prototype will mimic authentic and near-future products. Consequently, it is likely to draw customers to invest in the product before going to the development stage. While it undergoes testing, users will discover how to relate with it and understand expectations.

- It encourages innovations

As the product undergoes testing, each user would want to incorporate his ideas to appear in the end product. Such a process encourages creativity. One is likely to see the flaws in the current system and eventually enrich the system to improve.

- Prevents major problems

You can develop a prototype and test it before it goes to the actual market. If it is faulty, you have a privileged to refine it for better results. Consequently, you will save the company from undergoing financial loss if wrongly implemented.

- Improves the planning aspect

As you keep on testing a prototype, the team will be getting feedback from the users. The information you capture from the users will help you to plan for better versions. It will assist you in focusing on the user’s needs.

- Fast and simple to create

Do you know that a stakeholder can also create a prototype? You start by coming out with an idea. You present it on paper and let the designer make it functional.

How to make a product prototype?

One can use multiple methods to come up with a prototype. You can use both high-tech and conventional methods. Let’s take a closer look at some of the most commonly used methods.

Wood

Designers use wood to make prototypes that make metals. You can use wood to provide a physical impression of how the end product might look. Unfortunately, you may require a high amount of labor to fashion it into the desired product.

Foam Board or paper

You can use a paper or form board to present a rough idea of how the product is likely to be. The cool thing is that this method happens to be the cheapest of all. The only downside with such an approach is that it may not be accurate. Furthermore, it is also time-consuming.

Molding or Casting

You can use a resin or a plaster into a mold as a way of creating an object. The good news is that these molded prototypes have the upper hand over other methods due to their higher level of accuracy.

Unluckily, you need a high degree of labor for it to become a reality. Furthermore, you must be accessible to the right materials.

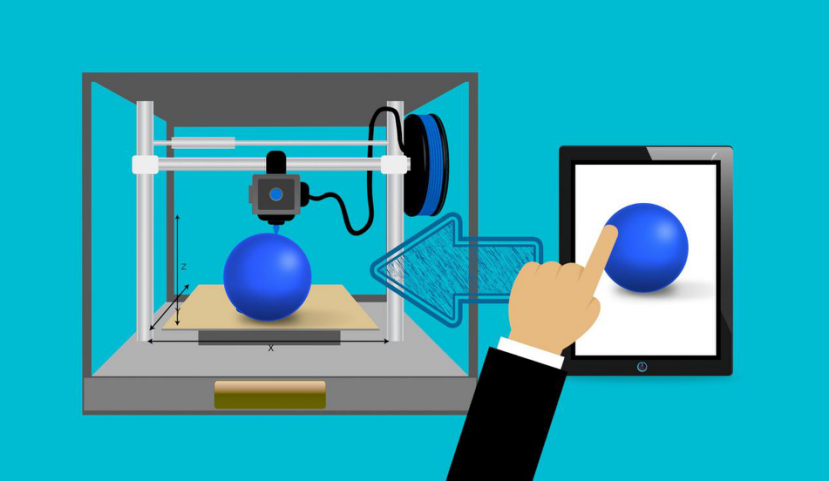

3D printing

You can use the 3D method for rapid prototyping. Once you feed your design in the CAD file, the process is accurate and fast. 3D printing makes use of several materials such as metal, plastics, fiberglass, and carbon fiber.

3D comes with unmatched speed and incredible quality. One can perform design revisions and embed them into the current designs.

How To Build A First Product’s Prototype

You can take the following steps in creating the prototype:

1. Create a sketch

You will have to put down your idea on paper. Draw it to help you visualize the prototype in more comprehensive details. It is advisable to begin by drafting it on paper before feeding it in the computer. You can use a notebook to keep your designs.

2. Create a virtual prototype

At this point, you may have to convert a digital sketch into a virtual idea. By using the 3D design, you can analyze the concept at all angles. You can now turn it into a material version for you to grasp the concept correctly.

3. Build a Physical Prototype

It is the action of transforming a virtual prototype into a physical prototype. You can alternatively consult an expert in designing at this stage. After completion, you can find errors that one can correct as you patent it.

It is normal to build an initial prototype with less costly materials.

4. Find a manufacturer

As you get a working prototype, you can apply for a patent at this level. It will also be reasonable to get a manufacturer to assist in producing the product. Make sure the costs are less expensive for you to maximize profit.

It will be reasonable to consult several manufacturers as you get the estimates. You will be in a position to determine the cost-effective materials to use.

Final Thoughts

Prototyping is a necessary process that gives an allowance to test a particular concept. As the originator of the idea, you must be consistent to make sure your concept undergoes proper revisions.

Concerning that, you should have a great team that will bring the correct feedback for you to improve on the flaws. Consequently, you will manage to get the final product with broader acceptance.

As your products begin to sell, it will be all smiles if you start to get a profit. You may use experts to actualize your dream. Remember to patent your idea to preserve your uniqueness.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.