When buying brass, you are likely to encounter two terms, red brass, and yellow brass. What are they, and which one should you choose? Read on to find out everything you should know between red brass vs. yellow brass.

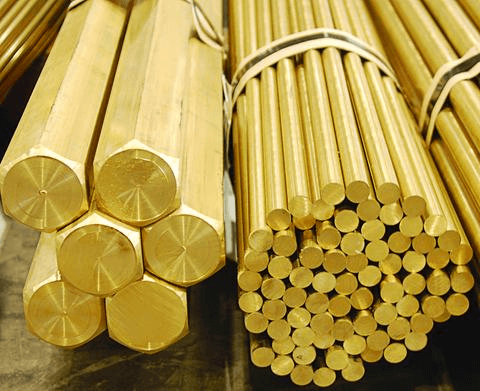

Simply defined, brass is an alloy of copper and zinc. These two metals exist in different percentages. Yellow brass is usually called gold brass, but it isn’t an equivalent thing. Red brass is sometimes known as rose brass or cast bronze.

But whether or not red brass is really the same thing depends on the quantity of copper within the metal blend. Yellow brass is what’s often most thought of as brass.

On the other hand, red brass usually draws mixed signals, especially after the copper. Material has been subjected to inspection.

Contents

What is Considered Red Brass?

Red brass features a reddish hue thanks to the high concentration of copper in its composition. This is the main reason why it is known as “Red Brass”. Due to its higher copper level, this type of brass is very valuable and sometimes recycled.

A red brass of lesser quality is named semi-red brass.

This red brass is lesser expensive to manufacture than the pure red brass and contains less copper and more mixtures of other metals, like tin or lead, also as zinc.

Red brass is used in many industries, including construction and industry mechanical parts like valves, sprinklers, and components utilized in various pumps. Red brass is also utilized in the making of musical instruments like trombones.

What is Red Brass Made of?

The red brass comprises of Copper Zinc and Tin metals. In most cases, the composition of this red brass is 88% copper, 8%-10% zinc, and 2%-4% tin.

The high percentage of copper is the sole reason why this brass always appears to be red. This composition also contributes to the physical and chemical properties of this brass.

Physical and Mechanical Properties of Red Brass

Before you choose red brass vs yellow brass, it is vital to know the figures behind each one of them.

The table below summarizes the physical and mechanical properties.

| Properties | Metric | Maximum |

| Melting point-liquidus | 1027°C | 1880°F |

| Melting point-solidus | 988°C | 1810°F |

| Density (@20°C/68°F) | 8.75 gm/cm3 | 0.316 lb/in3 |

| Tensile Strength | 269-724 MPa | 39-105 ksi |

| Yield Strength | 69-434 MPa | 10-70 ksi |

| Elongation | 55% | 55% |

| Poison ratio | 0.34 | 0.34 |

| Elastic Modulus | 117 GPa | 16969 ksi |

Red Brass Price

The high content of copper in red brass makes it more expensive than yellow brass. The pricing depends upon the quantity of lead or steel contamination. Red brass is free from high lead, and steel contamination fetches the best price.

Also, confirm that the guinea gold is sorted and separated out from other red metal alloys. Note that it’s going not to be easy for a traditional person to hold out the sorting. It is going to require some professional assistance from the best red brass manufacturer in China.

What is Yellow Brass?

Yellow Brass is basically a copper alloy that comprises about 60-70% copper, 30-40% of zinc, tin, and lead in traces. It must be free of iron, paint, plastic, washers, glass, etc.

The presence of more zinc makes it look more yellowish in color. It is brighter in color and more reflective than red brass. Thanks to its lower copper content, it’s priced lesser than the red brass.

Yellow brass is one of the most commonly used types of brasses. It’s used for a wide range of applications, mainly for household plumbing products. It’s also utilized in industry and for the manufacture of other items like keys, antennas, connectors, etc. Yellow brass is additionally wont to make musical instruments like saxophones and costume jewelry.

The expected of a yellow brass system is approximately 20 to 40 years.

Yellow Brass Price

The copper content in yellow brass is very different from the red brass. Since Yellow Brass contains relatively low copper in it, This directly means that it carries a lower price tag. To get a true value of your money, ensure that yellow brass is carefully separated from other brass scrap items.

The price of the Yellow brass is not fixed. Instead, it varies quite frequently. To make sure the best price, it’s advised to talk directly with yellow brass manufacturers and find out their pricing information.

Yellow Brass Properties

| Properties | Metric | Imperial |

| Hardness, Rockwell F | 58 | 58 |

| Hardness, HR30T | 15 | 15 |

| Tensile strength, | 315 MPa | 45700 psi |

| Yeild strength | 97.0 MPa | 14100 psi |

| Elongation at break | 65.00% | 65.00% |

| Shear strength | 220 MPa | 31900 psi |

Similarities between Red Brass and Yellow Brass

One of the key similarities is that both the red and yellow brass contains copper and zinc. Both red and yellow brass are utilized in constructing musical instruments.

Slide tubes, horn bells, and other instrument components are made from red or yellow brass. The brass type utilized in the instrument alters the sound produced. Different types of tubing, like plumbing and appliance parts, are made up of red or yellow brass.

Electrical and crafting wires are a standard product where both sorts of brass are used because both types are flexible, yet strong. Red and yellow brass are both used in decorative objects.

Differences Between Red Brass and Yellow Brass/Summary

The main difference between red brass and yellow brass is that the copper content. If you are unsure which type of brass, use a rasp or file to lightly sand and take note of the number of copper shavings.

Orange residue denotes red brass, and shavings of a straw hue demonstrate that the thing is yellow brass. Red brass is often recycled as is, but yellow brass must be purified to get rid of the less valuable metals alloyed with the copper that was used to make the yellow brass.

Typically guinea gold consists of a minimum of 85 percent copper. On the other hand, the copper composition in yellow brass is normally 60 percent or less.

A legitimate manufacturer that deals with red and yellow brass for your relevant application.

Related source link:

Brass vs Bronze: What is the Difference?

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.