When you want to use a piece of metal for any application but is not of the size that you want, what will you do? The most immediate option is to cut it into the required size or even shape. But which machine cutting method should you use?

There are different methods of cutting machines. The manual machine cutting methods have been used for quite a long time machines were cut manually using different types of tools.

It was up until in the 1970s when oxygen was tested for cutting metals. This led to the invention of laser cutting.

Contents

What is Laser Cutting?

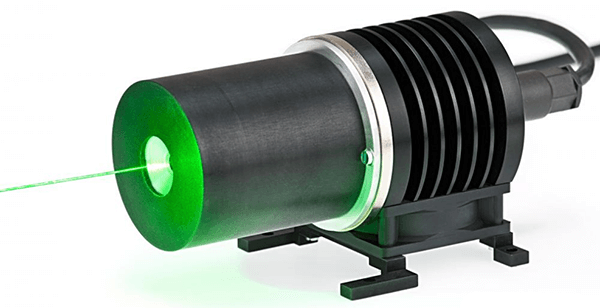

Laser cutting is a type of CNC cutting where a beam of light is used to cut material. Although it is mostly used for cutting metals, the beam can be used on other materials such as wood glass, silicon among many others.

Just when the laser cutting method was invented, the beam of light was channeled to the target object through a special glass. Later on, the beam was designed to be directed through fiber optics. This method increases the accuracy level of the laser beam.

There are special lenses that ensure that the beam of light focuses on one work area. This beam can cause the material in that area to burn, melt or vaporize. The method to be executed will depend on the type of laser cutting tool that you use.

Laser Cutting Services

Laser cutting services are provided by companies that have the tools and equipment to cut metals or other materials into what you want.

The service providers also have the right people to do the job. The laser cutters should have skills and experience to cut the materials accurately.

To ensure that you get the laser cutting services, ensure that you choose the best laser cutting companies in China. This is because these projects can be complex to be handled by any service provider.

Laser Cutting Materials

We know that laser cutting is mainly used for cutting metals, right? Well, there is a string of other materials that can be cut or trimmed using laser cutting.

Two key factors that determine whether a material is viable for laser cutting. These are the surface thickness and reflectance of the material.

The thickness of the material will determine the power of the beam that should be applied to the laser cutting tool. Reflectance is the measure of the radiation that will strike the surface of the material to be cut.

Apart from the metals(both ferrous a and non-ferrous), here are other materials that can be subjected to laser cutting;

-Wood

-Fiber glass

-Many types of wood except the one that oily woods

-Depron

-Mylar

-Glass

-Anodized aluminum among many others

What materials should not be cut by laser?

However, there are other materials that cannot be cut by this method. They include PVC, Epoxy, Polystyrene, Coated carbon fiber and materials that have glue or sticky medium at the back.

Types of Laser Cutting

Laser cutting is not all the same. Although the ultimate goal of the service is to cut a material, the process is executed in different ways.

There are three main types of laser cutting techniques. These are flame/reactive cutting, fusion cutting, and remote cutting.

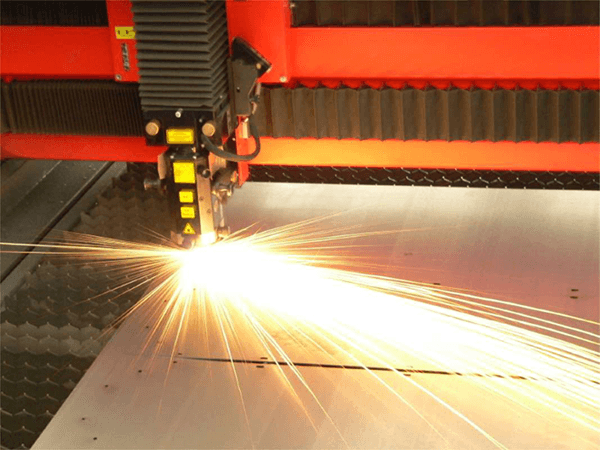

Flame or reactive laser cutting is where high-pressure oxygen is blown onto the material. This gas will react with the heated material creating a stage for the oxidation process. The material will start burning.

Fusion cutting is also known as a blow or melt laser cutting. In this process, nitrogen gas or another inert gas is used for blowing the molten material. Here also the material must be heated.

Remote cutting is where an intense laser beam is used for literally evaporating the target material. It is an ideal choice for cutting thin sheets of metals.

How Does Laser Cutting Work?

What is the Property of Laser Light that Makes it Ideal for Cutting Metals?

Probably you are wondering how the laser light can cut through different types of materials, especially metals. To make it more shocking, this cutting technology cuts through with high levels of precision.

To answer this question, you need to know how laser cutting work.

Image of how laser cutting works source Esabana

Laser light is a beam of high-intensity light that operates with a single wavelength or color. Since most laser beams have CO2 laser, they operated with the infra-Red wavelength. Keep in mind that this wavelength is invisible to human beings.

The diameter of the laser beam is 0.75 inches. It is emitted from the resonator laser which is responsible for creating the beam part. The beam can be channeled towards different directions by different mirrors before it is finally refocussed in one direction.

The focused beam will now go through the nozzle before hitting the metal sheet. This beam from the nozzle is accompanied by nitrogen or oxygen gases.

The focusing of the laser beam is done using a powerful lens. A curved mirror is usually an ideal option for this job.

The beam is focused on a specific area of the material that you want to cut. The density of the beam that is exiting through the nozzle can be controlled.

The high-density beam causes the heating impact on the material. It can also cause melting and vaporization. The beam is powerful enough to cause an oxy-fuel burning effect.

For the high-density metals, the beam will melt the material and the nitrogen gas will be used for blowing away the resultant molten material.

In a typical CNC laser cutter, the beam can be directed to any part of the metal or material. In doing so, it improves the quality of the cut. It is possible to control other operational parameters of the laser cutter.

Reliable laser cutting service providers are equipped with high-tech machines that can do the job easily and efficiently.

Custom Laser Cutting Services

There are many situations where you will want to get more than the general laser cutting services.

The most common reason is you want your metal to be cut in a special way. Maybe the material is delicate and needs some special forms of treatment.

Another reason is you want to get special shapes and designs from the laser cutting process.

Regardless of the reason, a reliable laser cutting company should be able to deliver custom cut on your material. They have laser machines and experts who can handle custom projects efficiently.

The secret of custom laser cutting is communication. Communicate everything that you want, and they will do the job.

What is the Cost of Laser Cutting Services?

Are you planning to have your laser cutting project done? One of the things that you should consider is the cost. This information will help you prepare appropriately for the project, especially when it comes to the financial aspects.

Usually, the price of laser cutting is calculated per the amount of work done. In most cases, it is the cost per inch of the material to be cut.

But still, there are many other factors that determine the cost of the laser cutting service. These factors include:

The type of material: Some materials can be easily cut by the laser machine while others are hard. This automatically means that the cost of laser cutting them will vary.

The cost of laser cutting will never be the same between carbon steel, copper, stainless steel, aluminum, or any other metal.

The thickness of the material: The cost will vary depending on the thickness of the metal. You are likely to pay more for cutting thicker materials than for thinner materials.

The quantity of the material: That is the volume of the material for the laser cutting project? You will pay more for laser cutting large quantities of metals than for low quantity.

Laser distance: This is the distance that the laser beam is expected to penetrate the material. You will pay more for cutting deeper into the machine than for shallow cutting.

Auxiliary services: Extra services for the laser cutting projects include packaging, cleaning, and transportation. These can also contribute to the ultimate price of the project.

The cost of laser cutting services also tends to vary between companies. The best way of knowing is to contact the laser cutting services companies directly. This way, you will be able to get the exact quotes.

Roche Industry: Laser Cutting Services in China

At Roche Industry, we specialize in providing custom laser cutting services in China. Our laser cutting services are highly competitive and reliable. We have years of experience in this industry, and this helps us to deliver flawless work.

With a powerful combination of experience and expertise, we are capable of working effectively on complex designs. We also laser cut different types of metals.

Equipped with high-tech laser cutting tools and skilled experts, we deliver laser cutting services without any delays. Simply contact us for reliable and affordable laser cutting services in China.

Related source links:

Handbook: The complete Guide to Laser Etching

Handbook: The complete Guide to Laser Drilling

Handbook: The Complete Guide to Laser Welding

Handbook: The Ultimate Guide to Selective Laser Sintering

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.