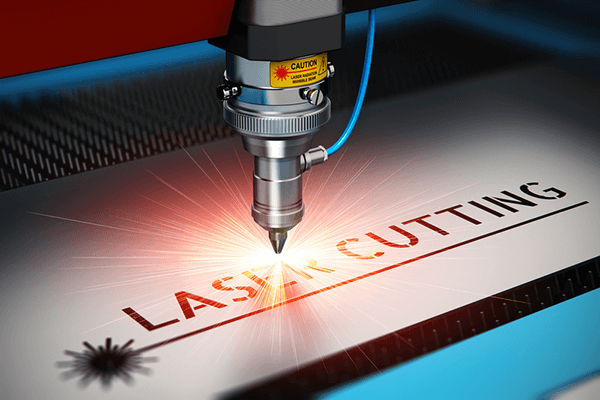

Ever thought of drawing figures or writing texts on the object? Well, this write-up will try to answer that question. With the emergence of laser technologies, you can perform such tasks more efficiently.

The laser technology makes use of a high power laser beam to make some shapes and drawings on objects. Interestingly, the most common laser is diode-based, which appears like a DVD burning drive.

Typically, you can control lasers through different magnetic fields, mirrors, or other mechanical means. With that in mind, let’s get a little deeper about this process.

Contents

What is laser etching?

Laser etching will happen when a beam heat triggers the surface of a particular material to melt. It is also a subset of laser engraving. As a result, the melted materials will expand, resulting in a raised mark.

Laser etching will not cause a depth that is not more than 0.0001 inches. In other words, it is usually shallow.

In laser etching, the heat that comes from the beam will melt it and not vaporize it. The most common materials used are metal and glass. The material will expand and create a raised cavity.

Furthermore, the process will modify the characteristics of the material used, such as reflectivity. It may also create a contrast with the surrounding.

How Does laser etching Work?

You can use laser etching to generate specific marks like barcodes, serial numbers, and data matrix codes. The entire process must cause a surface to melt. The melted surface will expand to create bumps that range to 80 microns high.

Generally, you can follow the below steps when etching a surface.

Step 1: Pulsing a Beam

Do you know that all the marking techniques have one thing in common? Indeed, one must pulse a laser beam. After that, it will begin to release some energy in a particular interval. For instance, just in a second, a 100W pulsed laser can comfortably release 100, 000 pulses.

One pulse equals one millijoule of energy. One can adjust the system, plus, its parameters as a way of controlling the amount of the released energy.

Here, the crucial parameters to observe are line spacing and pulse spacing. When you make them closer, you will experience a high concentration of energy.

Step 2: Absorption of energy

As the beam hits the surface, the material will start absorbing energy. The same energy will convert into heat. Interestingly, the material will reflect some of the beam energy. Luckily, it will also be absorbing and converting it to heat energy.

The absorbed energy must heat enough to melt for one to begin the etching process. It is noteworthy that each material has a different absorption rate.

For instance, metal happens to absorb more energy from specific wavelengths that come from solid-state lasers. In that regard, you can rely on solid-state lasers while marking metals.

A perfect example is this: Aluminum will absorb 5% of beam energy. Iron metal will absorb 30% of the beam energy. On the other hand, steel will absorb more than all.

Step 3: Melting the surface

Beam energy will get transformed into heat. Consequently, the temperature of the material will rise until they reach a boiling point. High heat will cause the surface to melt and become malleable. At this point, the shape can change.

Different metals have different melting points. For example, Aluminum 6061 has a melting point of 585 degrees Celsius. Magnesium metals have a melting point of 650 degrees Celsius among others.

Step 4: Expansion

The heated material will melt, expand, and cool down in a small duration of milliseconds. There are specific changes that will occur within the same surface. Also, the roughness of the surface will change to create permanent markings.

Step 5: Appearance of High Contrasting Markings

Different surface patterns will cause color changes. Luckily, you can use black and white colors if you want high-quality markings. You can adapt this technique to various applications.

You can perform a laser etching at different frequencies. The frequency will primarily affect how it behaves with different materials. By frequency, we exactly mean the wavelengths of light that the laser will produce.

For instance, one can use glass material. You can etch the glass to create text, image, or pattern. One can still use the low-power CO2 laser to etch the glass. Unfortunately, the same laser will not work well on the metal materials.

The low-power CO2 type of a laser will work well on glass, cork, or wood. It is also compatible with plastics. The same laser has a suitable frequency to etch on glass

Meanwhile, for the demonstration of how it works, let’s use glass as an example. The laser beam will first reach the glass materials. It will heat it together with any impurities in the same glass.

Both the air and water that gets trapped in the material glass will begin to expand as it heats up. Consequently, there will be microscopic fractures on the glass surface. Eventually, you will see some chippings or fractures, which are the marking on the glass.

Typically, there are several methods of etching glass. Among them, engraving takes the lead. The technique is less expensive, faster, more forgiving, and versatile. You should learn the best methods to etch glass if you want to begin a glass etching business.

Materials Used for Laser Etching

Laser etching is a process that does not discriminate materials. All the materials that can undergo cutting are also suitable for laser etching.

- Glass: Glass is among the best materials that one can use to etch. The only downside is that you will not etch cylindrical of rounded items. But you can etch a flat glass.

- Iodized aluminum

- Coated and painted metals

- Stone and brick

- Stainless steel

- Titanium

- Lead

- Magnesium

How to select a laser etching machine

Laser etching is another technique that comes to improve the quality of your product. The operator uses the laser etching machine due to its accuracy, quality, and the marking speed. Before you select your desired apparatus, you must check the following parameters.

a) Permanence

Inscribing process is ordinarily complex. Many technologists had been looking forward to making the marked information to last for long. The good news is that laser etching has all the answers. All the signs that these machines create are residents of chemicals.

Moreover, the same signs are permanent. One can trace the details of the inscribed information as long as the object is within reach.

b) High-Quality

The process of etching results in high-accuracy, precision, and resolution. The method will restore the most delicate and precise imprints. One will use sophisticated artworks to appear on the objects to feed your eye.

Laser etching is among the best technology that one should use to perform such complicated tasks. The final marks will appear impressively since the automated method is also accurate. It is a suitable method that many will use it on the internet of things.

c) Automation and Speed

The process of marking and creating designs on your object appears to be complex. It may also require more time to get a perfect output. The cool thing is that etch machines are far better to produce results within a short time.

The machines have an integrated automation feature that enhances high speed inscribing. The output will require no-post processing. It also minimizes downtime. One can use a programmable software to create various designs and patterns.

d) Safety and Eco-friendly

The machine should not pose any threat to your health. Also, the device should not have dangerous chemicals. Furthermore, the device should not emit harmful components in the atmosphere.

Moreover, it should have safety features to protect you from any eventuality. In other words, it should minimize accidents while you are operating it.

e)Budget-friendly

Most of the laser etching machines come in moderate pricing. However, some may cause you to break your bank before you access them. You must settle for the one that will not strain your budget.

Benefits of Laser Etching

- The process is fast, as one can achieve the outcome within a short period.

- The automated system will give clear results with precision.

- The method is highly accurate and reliable.

- Due to high speed, one can perform mass production.

- The system is user-friendly since you can only program it to do particular tasks.

In conclusion

People are ever-increasing in knowledge. As a result, they applied this knowledge to better their lives. The same case applies to technology too. Some traditional way of approaches are becoming null and void.

Laser etching is a new concept that is taking over from other conventional methods. Firstly, it is fast and more accurate. You can accomplish a task within no time with more precision. However, you must understand the dynamics of this method to manage it effectively.

Do you want to etch your materials and improve quality? Indeed, you should not despair. Seek the services of an etching machine.

Related source links:

Handbook: The complete Guide to Laser Drilling

Handbook: The Complete Guide to Laser Welding

Handbook: The Complete Guide To Laser Cutting

Handbook: The Ultimate Guide to Selective Laser Sintering

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.