Since each type of metal has unique properties, its usage or applications also tend to vary.

Every single day, there is a likelihood that you have come across different metals. In this article, we are going to explore the types and properties of metals.

Contents

Steel

It goes without question that steel remains to be the most popular type of metal in the world. Of course, there are numerous reasons why this remains to be the case.

By definition, steel is basically an alloy of iron and carbon. In most cases, the ratio of these two elements is 99% to 1% respectively. However, there could be some slight variations of this composition.

One of the key properties of steel is tensile strength and toughness. This metal does not deform easily. It also has a high strength to weight ratio, a feature that makes it light.

There are other types of steel which we are steel viewed as different types of metals.

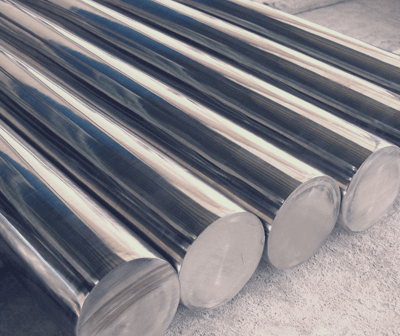

Stainless Steel

Stainless steel is basically an alloy of steel that is known for its extraordinary strength and corrosion resistance.

One of the most noticeable features of this metal is the amount of chromium in it. Stainless steel has a minimum of 11% chromium. This composition protects the iron from rusting.

High levels of chromium also make this steel to be resistant to corrosion. On the other hand, it has a very low percentage of carbon. It ranges between 0.003% to 1%.

Other elements that are found in stainless steel include nitrogen, aluminum, molybdenum, silicon, selenium, titanium, and sulfur.

Carbon Steel

As the name suggests, this type of steel alloy contains a relatively higher percentage of carbon content. It can be as high as 2.1%. However, there is no specified minimum amount of other elements such as silicon, titanium, nickel, molybdenum, tungsten among other elements.

The presence of carbon gives this metal higher durability, lower melting point, and high malleability. It also makes it more efficient when it comes to heat distribution.

In terms of applications, carbon steel is used for making cars, bridges, fridges, high-strength wires, cutting tools among other heavy-duty products.

Alloy Steel

Alloy steel is basically a type of steel that is alloyed or mixed with different types of elements. The alloy composition makes up to between 1.0% and 50% depending on the types of elements used. This mixture helps to improve the mechanical properties of steel.

Alloy steel is further divided into two broad categories. These are low alloy steel and high alloy steel. Again, it all depends on the quantities of the alloys used.

Some of the commonly used elements or alloys include manganese, chromium, molybdenum, vanadium, boron, titanium, cobalt, copper, tungsten, and niobium.

Alloy steel has an array of desirable features such as mechanical strength, hardness, corrosion resistance, and heat resistance.

This metal is used for unique applications such as making jet engines, automotive engines, turbine blades among others.

Iron

Although it is always regarded as old metal, the usefulness of iron cannot be easily ignored. This metal still enjoys a wide range of applications in the modern world.

The fact that iron is the main ingredient means a lot. It basically means that without iron we won’t have steel.

Iron is used for making cookware and skillets. It is an ideal choice for making the non-stick surface of most cookware.

This metal is also used for making automotive parts, machinery parts, and even for building/ construction parts.

Aluminum

Although it is always considered as an element, aluminum is also a type of metal. It is a silver-white metal, an appearance that makes it look lustrous.

Aluminum does not exist naturally. This is because it easily reacts with other elements such as oxygen to form a compound. The most common natural-occurring aluminum is the sulfates.

The first aluminum was discovered in 1824 and after many years, people learned how to produce large volumes of aluminum for commercial use.

The excellent strength to weight ratio is one of the reasons behind the popularity of aluminum metal. The metal is highly malleable hence can be used for making a wide range of products.

Being non-ferrous, aluminum does not rust easily. However, it can oxidize and corrode when mixed with other chemicals.

Copper

Copper is another ‘old-fashioned’ metal that is still widely recognized even in the modern world. Pure copper metal has an orange luster and tends to be a little bit shiny.

Copper is highly ductile and very malleable. This means that it can be easily formed into different products. This explains why copper is used for making items such as jewelry.

Perhaps the most popular application of copper metal is for making the electric cable. This is due to the fact that this metal is a good conductor of electricity. It is also a good conductor of heat hence can be used for several thermal applications.

Copper is also durable and can be used for making products such as pipes and statues.

Magnesium

Magnesium is one of the metals that belong to the Group 2 elements. It is one of the most reactive metals.

Magnesium, in most cases, tends to exist as an alloy whereby it shares some of its desirable properties with other types of metals.

When compared to other metals such as aluminum, magnesium is a very light metal. Despite carrying little weight, magnesium is quite strong. It can be used for some heavy-duty applications.

One of the most popular uses of magnesium is in the automotive industry. Some parts of the vehicles such as rims and engine blocks are made of magnesium. Some automakers prefer using magnesium instead of aluminum. The main disadvantage is it corrodes easily.

Brass

Brass is basically an alloy that comprises of copper and zinc. The proportions of these two metal elements tend to vary depending on the desired mechanical and electrical properties.

Other elements that can be found in bras metal include lead, arsenic, phosphorous, silicon, aluminum, and manganese.

Some of the properties of bras include low melting points, and easily malleable. Also, this metal does not easily spark.

For years brass metal has been used for decoration. This is mainly because of its gold-like luster. The unique appearance of brass makes it ideal for making items such as drawer pulls, doorknobs, artifacts, and musical instruments.

Bronze

Bronze is another type of metal that is an alloy of copper. The only difference with steel is it has tin instead of zinc. The 12% steel in the bronze metal is responsible for its hardness and tenacity. In fact, bronze is physically and mechanically stronger than pure copper.

Other elements make up the bronze alloy. They include aluminum, nickel, manganese, and zinc.

Each of these elements has a direct impact on the physical and mechanical properties of the bronze metal.

There is a rich history behind the application of bronze. It is a common feature in most ancient churches whereby it was used for making bells. The modern applications of bronze include making sculptures and music instruments.

Titanium

Titanium is ranked among the top 10 most abundant metals on earth. Although it is easily available, the challenge comes in refining it. This is the reason why this metal is quite expensive.

Titanium metal has a high strength to weight ratio. Very few metals can match titanium when it comes to this property. Probably this is the reason why titanium is used for making aircraft parts.

Titanium is also classified as a biocompatible metal. This means that it does not trigger reactions with the body. This feature makes it ideal for creating body implants.

The metal has a high nitrogen content and is corrosion resistant.

Zinc

Zinc is quite a popular metal that enjoys a wide range of applications. It is produced by roasting sulfide ores and placing the resultant product in sulphuric acid.

Pure zinc has a low melting point, a feature that makes it easy to cast. The metal can be easily melted and molded into different products.

Zinc is popularly used for coating other metals with the aim of protecting them from rusting among other dangers. A perfect example is galvanized steel or iron. They are basically deep in molten zinc which will then form a protective coating.

Tungsten

Also, know as Wolfram, Tungsten is categorized under rare metals. This simply means that it is not easily available even though it is a natural-occurring metal.

Tungsten must be combined with other elements and chemicals in order to attain its desirable properties.

A significant percentage of tungsten in the market is used for making tungsten carbide. This material is tough and abrasive such that it is used for cutting other metals.

Like zinc, tungsten is also used as an alloying metal. The ability to retain its state under extremely high temperatures makes it an ideal metal for making parts of a rocket.

Nickel

Nickel is another popular metal that has many different uses. One of its common applications is for making steel. Nickel plays the role of hardening steel and making it tough. It also increases the corrosion resistance of the steel metal.

Another common use of nickel is for making coins. Equipment that is used for storing chemicals is also plaited with nickel. The silvery luster of nickel makes it an ideal metal for decorations.

Cobalt

Cobalt is a ferromagnetic metal that is characterized by a bluish-white lustrous. It is a brittle metal that can easily react with different chemicals. It is capable of retaining its magnetic properties even at high temperatures.

Cobalt has a high melting point which is almost 3000°C. In terms of appearance, it is similar to nickel and iron.

This metal is predominantly used for making alloys. It can be easily alloyed with other metals such as nickel and iron. Satellites are made of cobalt, tungsten, and chromium alloy.

Cobalt is also used for electroplating due to its tensile strength and high resistance to oxidation.

Tin

Tin is easily identified by its silvery luster and a yellow hue. It is a natural- occurring element that exists in the rocks. However, it is a scarce element.

Tin is a highly malleable metal. It can be easily subjected to different types of metal processing methods such as spinning and rolling.

This metal has a low melting point hence not suitable for extremely high-temperature applications.

The high adhesive property of steel makes it ideal for cleaning other metals such as steel. It can also be used for plating iron.

Lead

Lead is a popular metal that is characterized by its softness and malleability. This also means that it has a low melting point and can be cast into different products. It is relatively a heavy metal that has high density.

Lead is popularly used for making paint and bullets. However, its usage has been on the decline in recent years due to the health risks that it poses.

Chromium

Chromium is a physically hard element after carbon and maybe a diamond. It is usually used as an alloy so as to improve the strength of other metals.

The metal has a high melting point which is approximately 2000 degrees Celcius. In terms of appearance, chromium has a unique reflection and can be used to improve the surface finishing of other metals.

Silicon

Silicon is usually categorized as a metalloid. This simply means that it posses the properties of both metals and non-metals.

Silicon has a high melting but does not conduct electricity. This is why it is not considered a full metal.

Lithium

Lithium is categorized as a soft metal or a metal alkali group. It has a silvery-white luster that makes it look attractive. Lithium is used for improving the strength of glasses and ceramics.

Conclusion

With this list of metals, you can identify one that will suit your application. Of course, your choice will be based on the properties of the metal.

In case you want to process the metal before using it, let the experts do the job. This is why we at Roche Industry provide different metal processing and treatment solutions.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Handbook: The Ultimate Guide To Metal Spinning

Handbook: The Ultimate Guide to Metal Casting

White Paper: The Ultimate Guide To Metal Stamping

Handbook: The Complete Guide to Metal Bending

What are the Strongest Metals on Earth?

What’s Difference Between Expanded Metal and Perforated Metal?

Everything You Should Know About Ferrous Metals vs Non-Ferrous Metals