When choosing metals for whichever applications, you will always be torn between two main types of metals. These are expanded metal vs. perforated metal. Each of the metal has unique properties that characterize it.

When choosing metals for whichever applications, you will always be torn between two main types of metals. These are expanded metal vs. perforated metal. Each of the metal has unique properties that characterize it.

The differences between these metals can be because of the material, chemical composition, performance, and structure. At the end of it all, you will have to make a decision on which metal to choose. In this article, we are going to look at the differences between expanded metal vs. perforated metal.

Contents

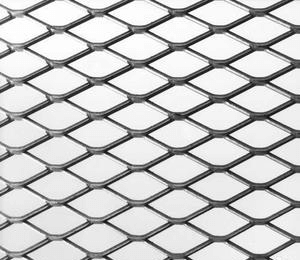

What is Expanded Metal?

An expanded metal is a type of metal that has been stretched and cut to form a distinct shape and pattern that takes the shape of a mesh. The stretching process end sup creating diamond shapes on the mesh even though you can still achieve other shapes from the process.

The pattern of the mesh can be on a straight line where all the rows and columns are aligned, or it can be staggered (no alignment). The size of the open area on an expanded metal will determine the amount of fluid, air, or light that should pass through. Usually, the application area of the expanded area will determine which size to choose.

The most common metals that can be expanded include aluminum, stainless steel, cold, and hot rolled steel, among others.

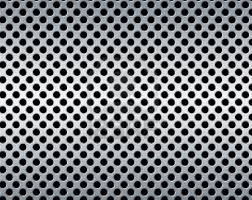

What is Perforated Metal?

Perforated metal is a type of sheet metal that has been mechanically punched or stamped so as to have holes on its surface. These holes come in different shapes and designs. Perforated metals are also known as perforated plates, perforated sheets, or perforated screens.

Different types of metals can be subjected through the perforation. They include aluminum, stainless steel, brass, cold rolled steel, hot rolled steel, tinplate, copper, among others.

Modern perforations are done using different types of metal machining tools. They improve quality and can make large volumes of perforated metals within a short time.

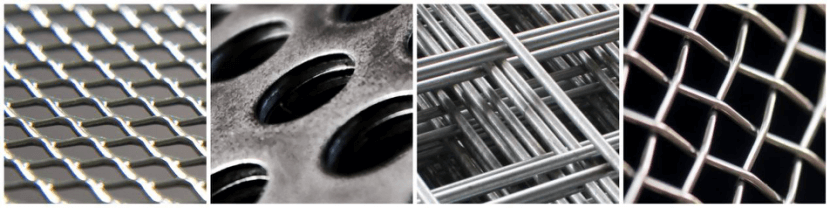

Manufacturing Process: Expanded Metal vs Perforated Metal

The first key difference is the process that is used for manufacturing these metals. The expanded metal is made by creating several slits on a metal sheet. The sheet is then stretched or expanded to create diamond-shaped patterns.

The raised strands of the metal sheet will, later on, be flattened so that the whole metal sheet adapts to a uniform shape.

Perforated metal, on the other hand, is created when a sheet of metal is fed into a punching machine. The machine will create several holes that come in different shapes and designs. The perforations can be on a straight line or staggered.

The size and number of holes can also vary from one metal sheet to another. In some metals, you may have to create several perforations while, in others, you will make a few perforations. It all depends on what you intend to use the metal sheet for.

Applications: Expanded Metals vs. Perforated Metals

There are some slight differences when it comes to the application areas of the expanded metals vs. perforated metals.

Uses of expanded metals

Expanded metals are mainly used for making grates, fences, and walkways. These metals are strong, durable, and cost-effective hence suitable for such large-scale applications.

Expanded metals can also be used as a type of filter in the construction industry. The openings on the metal sheet will allow passage of fluid air and small objects while preventing large objects.

In the field of art, expanded metals are used by sculptors for carving 3D pieces of art. These metals can also be used for making packages in any industrial application.

Expanded metals are also used in the field of architecture. In this field, these metal sheets can be used for making screen material, which can be transformed into different architectural designs. 3D graphic images can then be obtained from these materials.

Uses of perforated metals

Perforated metals have a wide range of applications. In the field of architecture, perforated metals are used for making sunshades, cladding, fencing screens, and the infill panels.

This type of metal is also common in the food and beverage industries. It is a common feature in the sorting machines that are used for processing food and beverages. Various equipment in the fish farming and grain storage silos are made of this metal type.

Perforated metal is used in the automotive industry. Different parts of a vehicle, such as air filters and radiator grilles, have this metal.

The use of perforated metals profoundly characterizes the fields of construction and material development. The metal is used for making different products such as facades, ventilation grilles stair treads, among others.

Advantages: Expanded Metal vs Perforated Metals

The table below summarizes the benefits of expanded metals and perforated metals;

| Expanded Metals Benefits | Perforated Metal Benefits |

| High and unique aesthetics | Offers high aesthetic value |

| Strong and durable | Very versatile |

| Cost-effective | Durable |

| Lightweight | Flexible |

| Desirable acoustic properties |

Which is the Best Between Expanded vs Perforated Metals

From these differences of perforated vs. expanded metals, you may be wondering which one to choose. The truth is there is no perfect metal between these two. Since each type of metal has unique features, your choice will be determined by the application areas of each metal.

Once you find out your needs, you will be in a position to choose the right metal type.

| Expanded Metal | Perforated Metal | |

| Cost | Low | Medium or high |

| Metal fabrication | Rolling, slitting, stretching | Metal Punching |

| Waste metals | Almost zero | High volumes of waste |

| Flexibility of design | Not very flexible | Very flexible |

| Stability | Very stable | Not very stable |

You can watch this video to know more differences between expanded metals vs. perforated metals.

Roche Industry: Expanded and Perforated Metals Fabrication

Would you like your blank metal sheet top to be processed? Whether you want the metal to be perforated or expanded, always seek the service from professionals. This is why we at Roche Industry ensure that you get the best expanded and perforated metals

We can perforate and expand the metal sheets according to your needs. We have machines that can do these jobs with the highest levels of precision. Our technicians are qualified and experienced in performing different metal machining services.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Top 20 Different types of Metal You Need to Know

Handbook: The Ultimate Guide To Metal Spinning

Handbook: The Ultimate Guide to Metal Casting

White Paper: The Ultimate Guide To Metal Stamping

Handbook: The Complete Guide to Metal Bending

What are the Strongest Metals on Earth?

Everything You Should Know About Ferrous Metals vs Non-Ferrous Metals